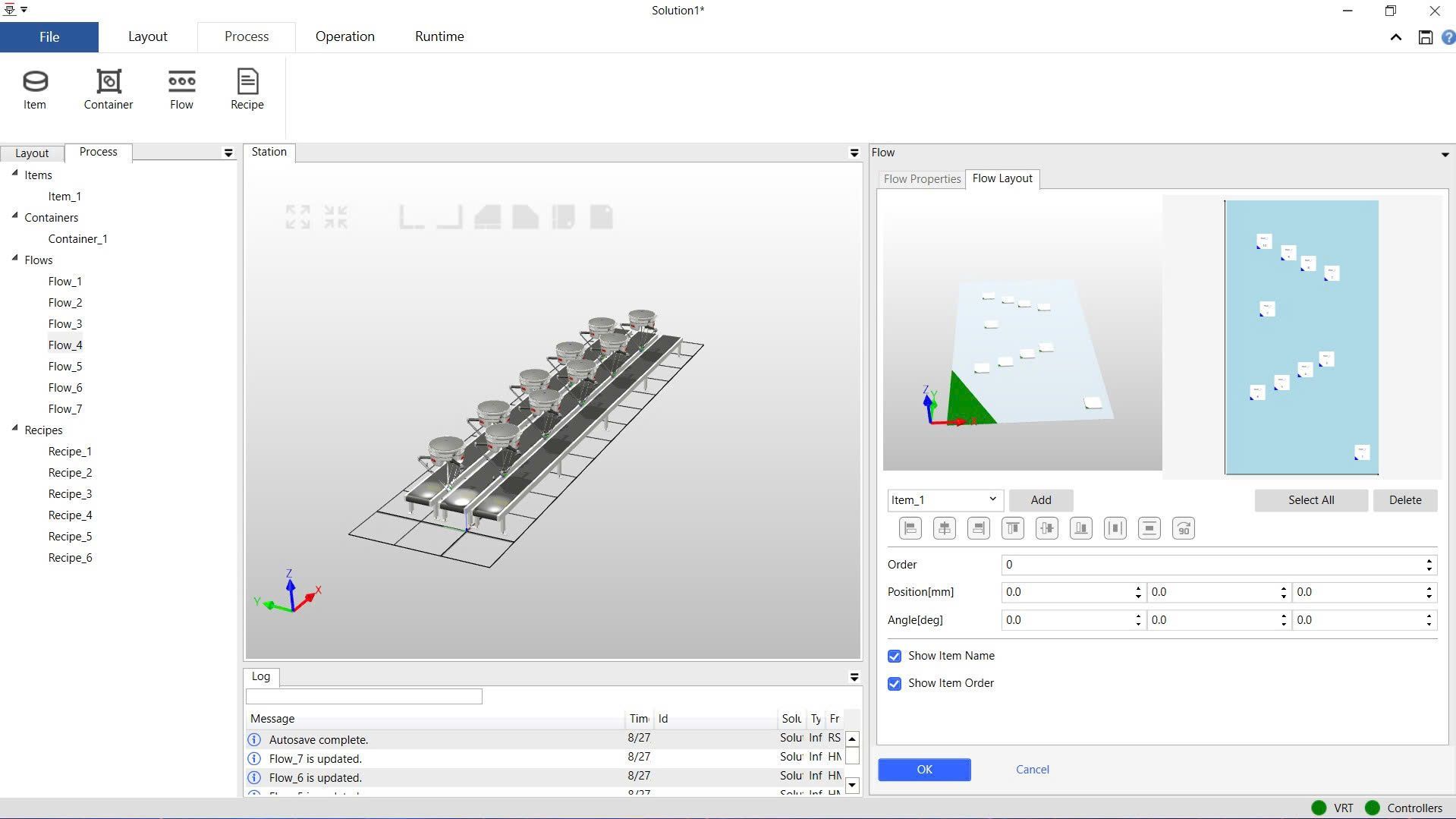

Vision Distribution Enhancement for Pickmaster Twin 3 - Pick & Place Applications

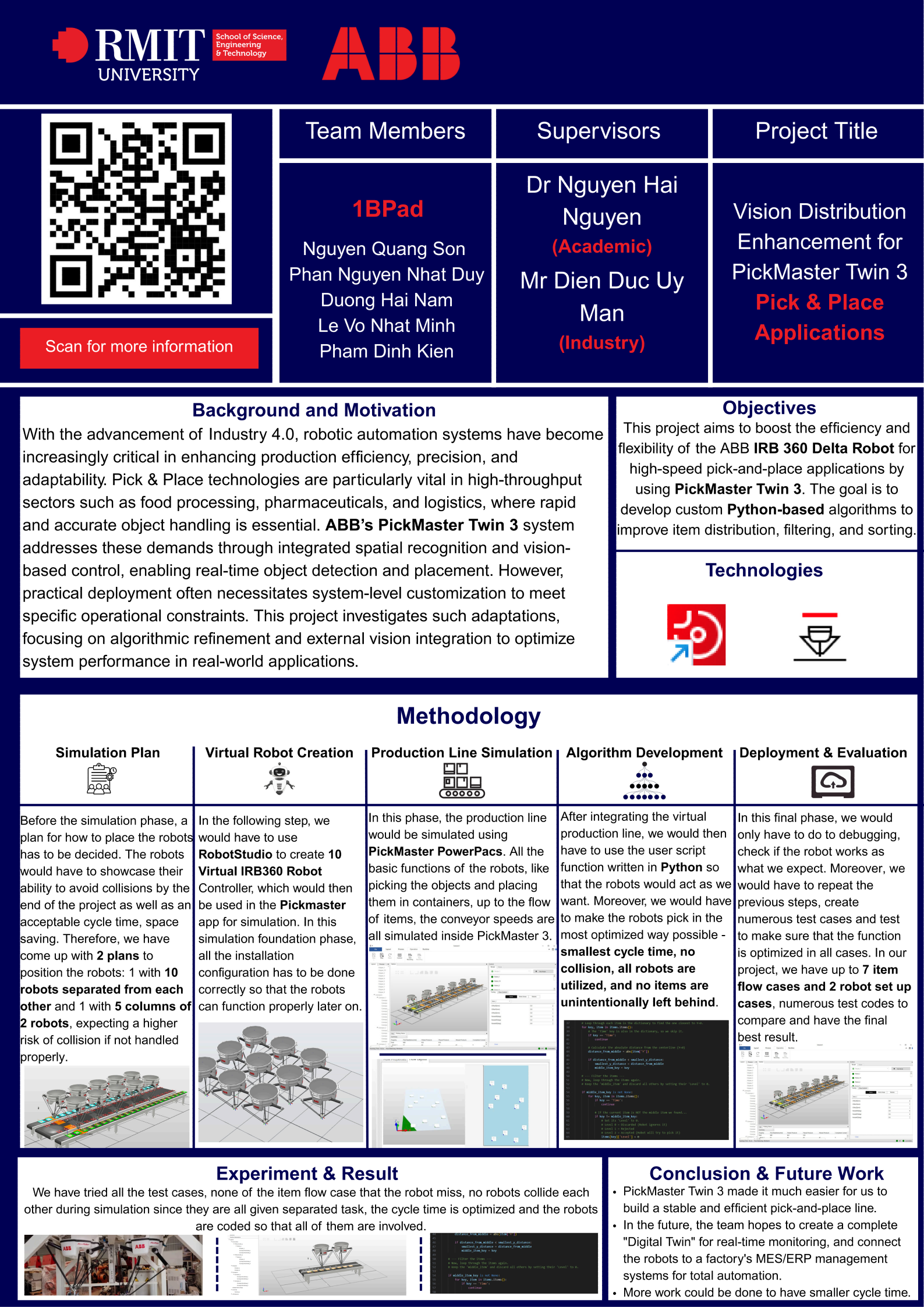

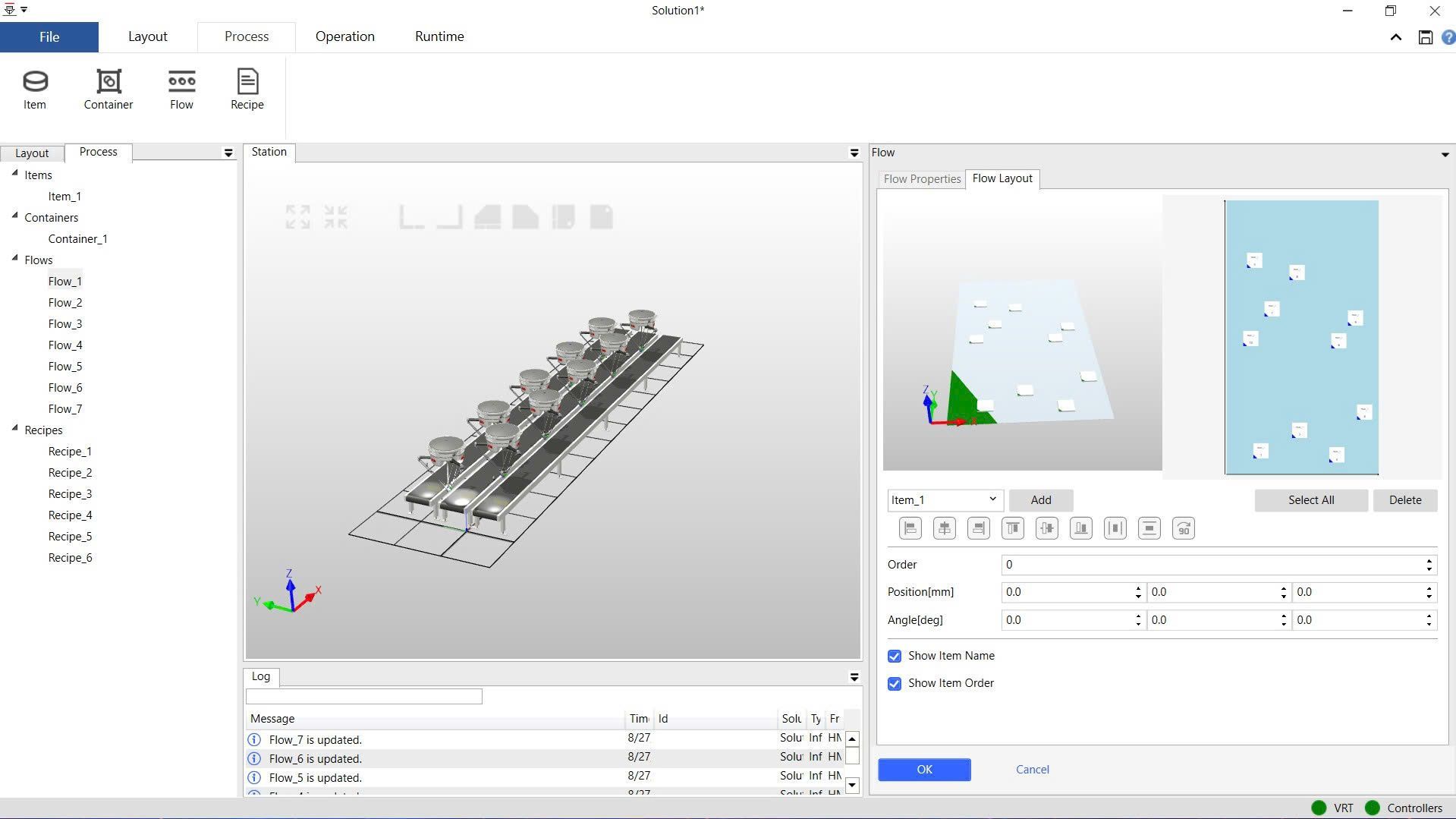

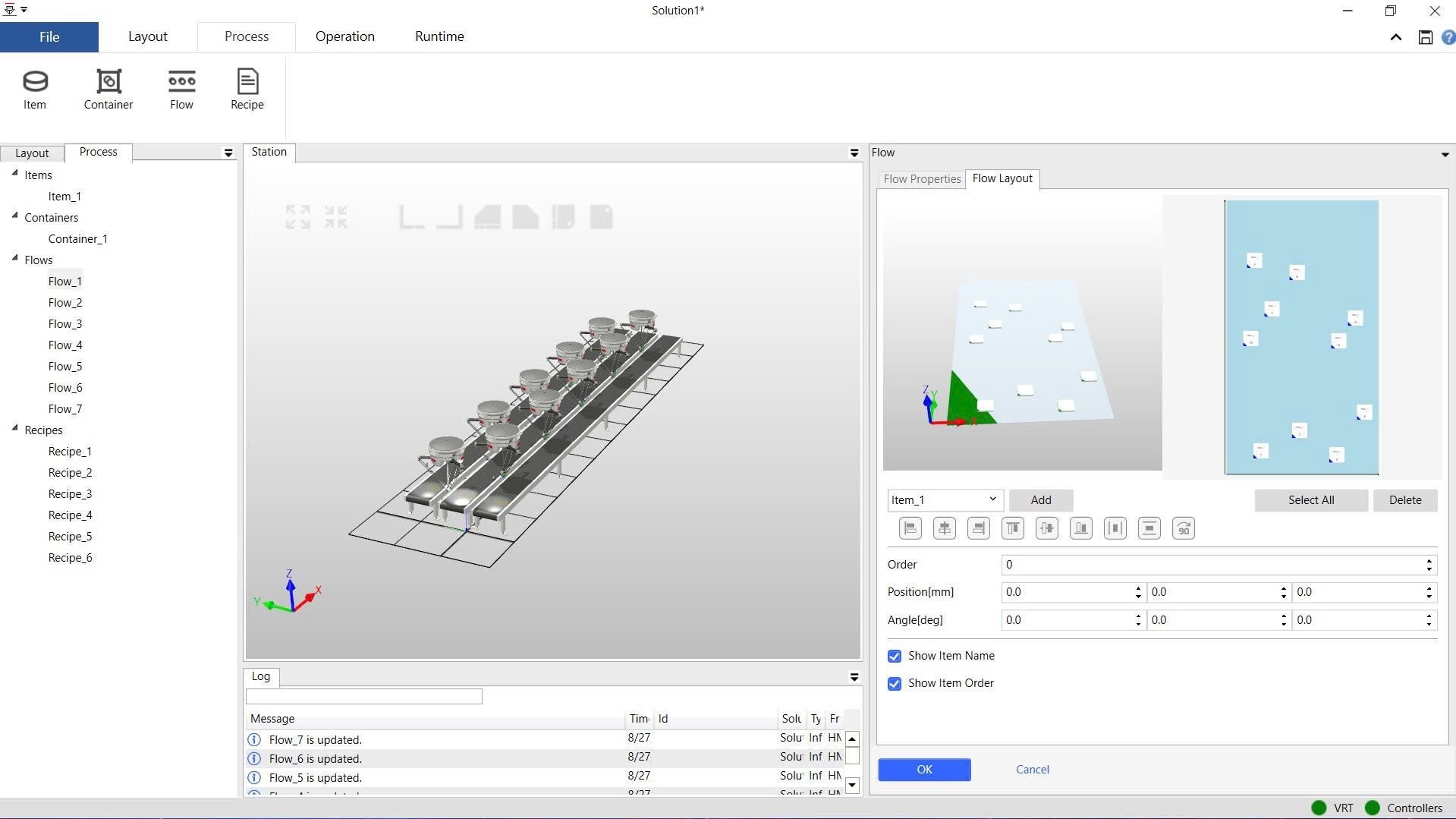

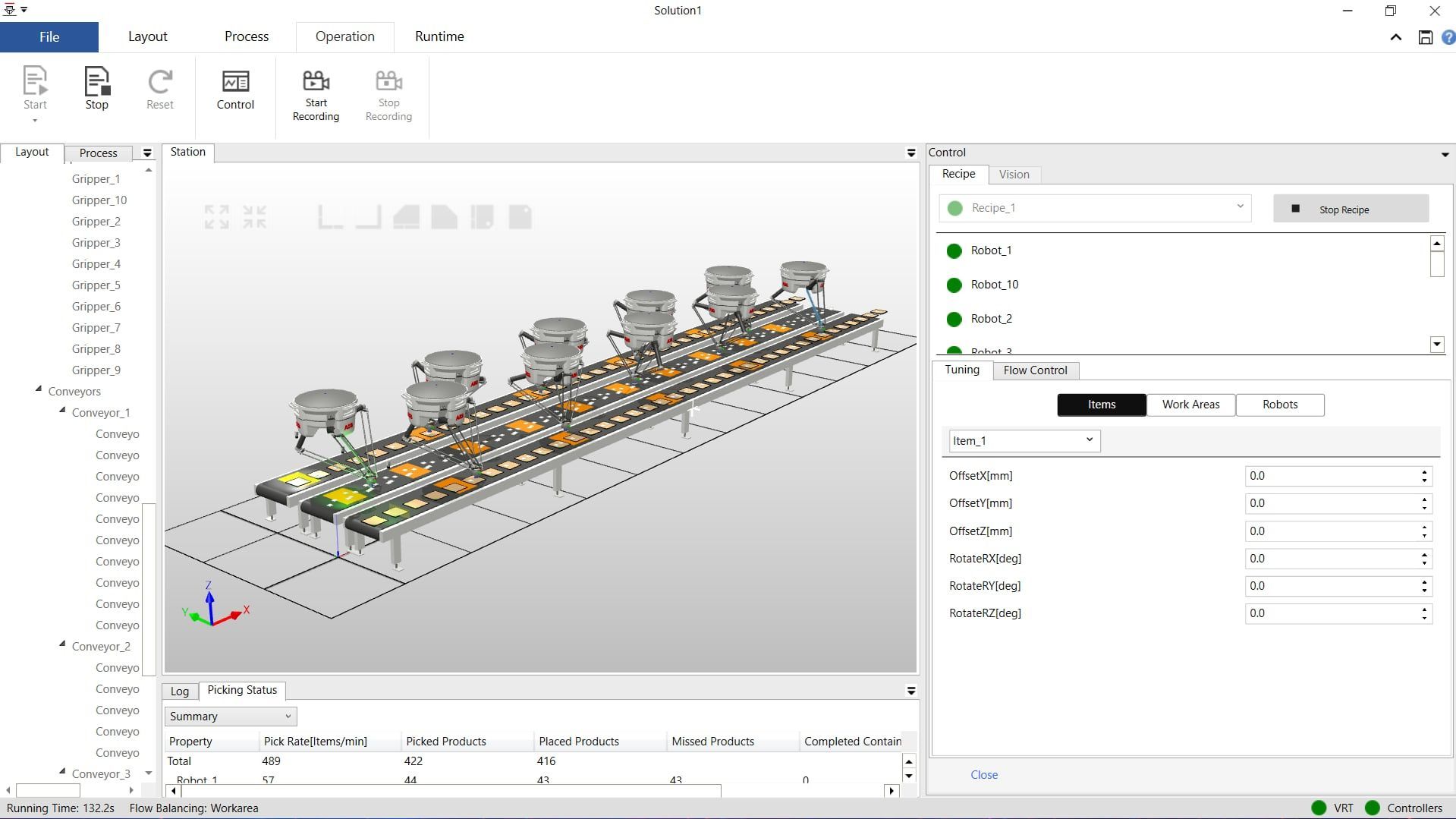

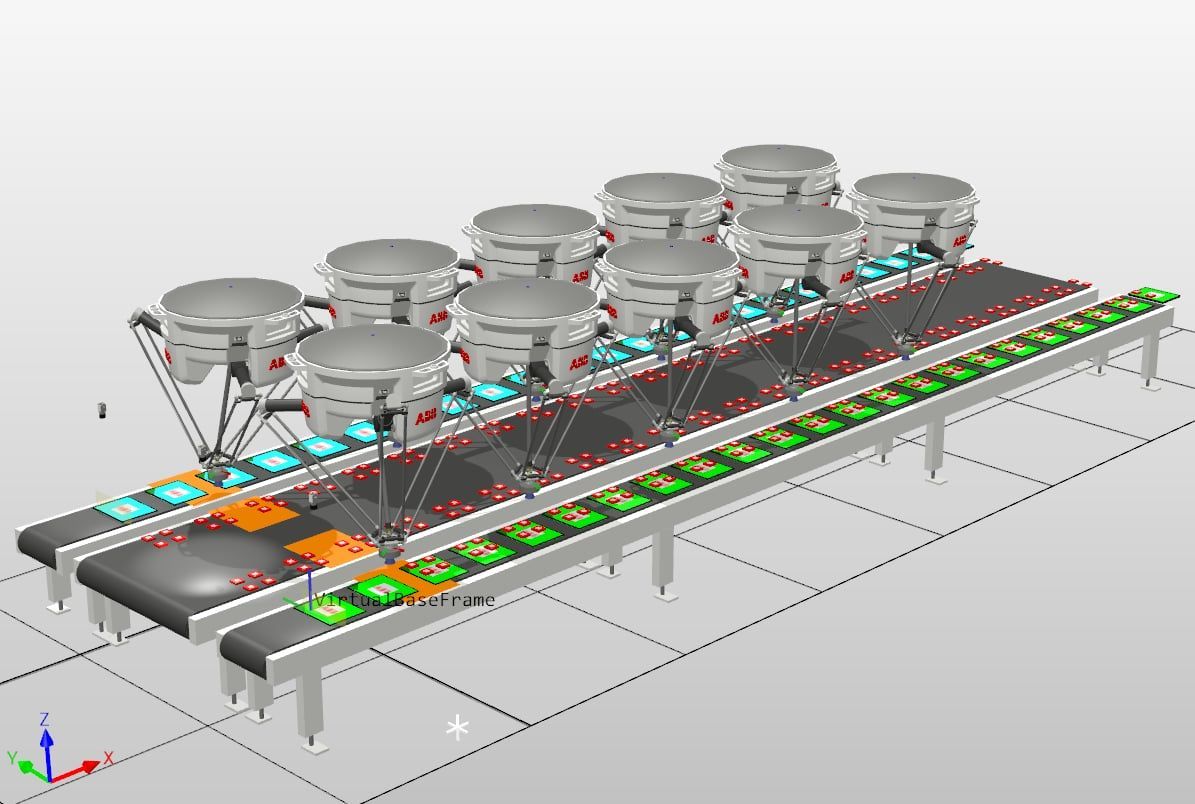

This project focuses on advancing the visual item distribution and sorting capabilities of the ABB IRB 360 Delta Robot, employing the PickMaster Twin 3 software for Pick & Place automation. The primary objective is to customize Python-based control algorithms and integrate third-party vision systems to meet specific application requirements in high-speed industrial environments.

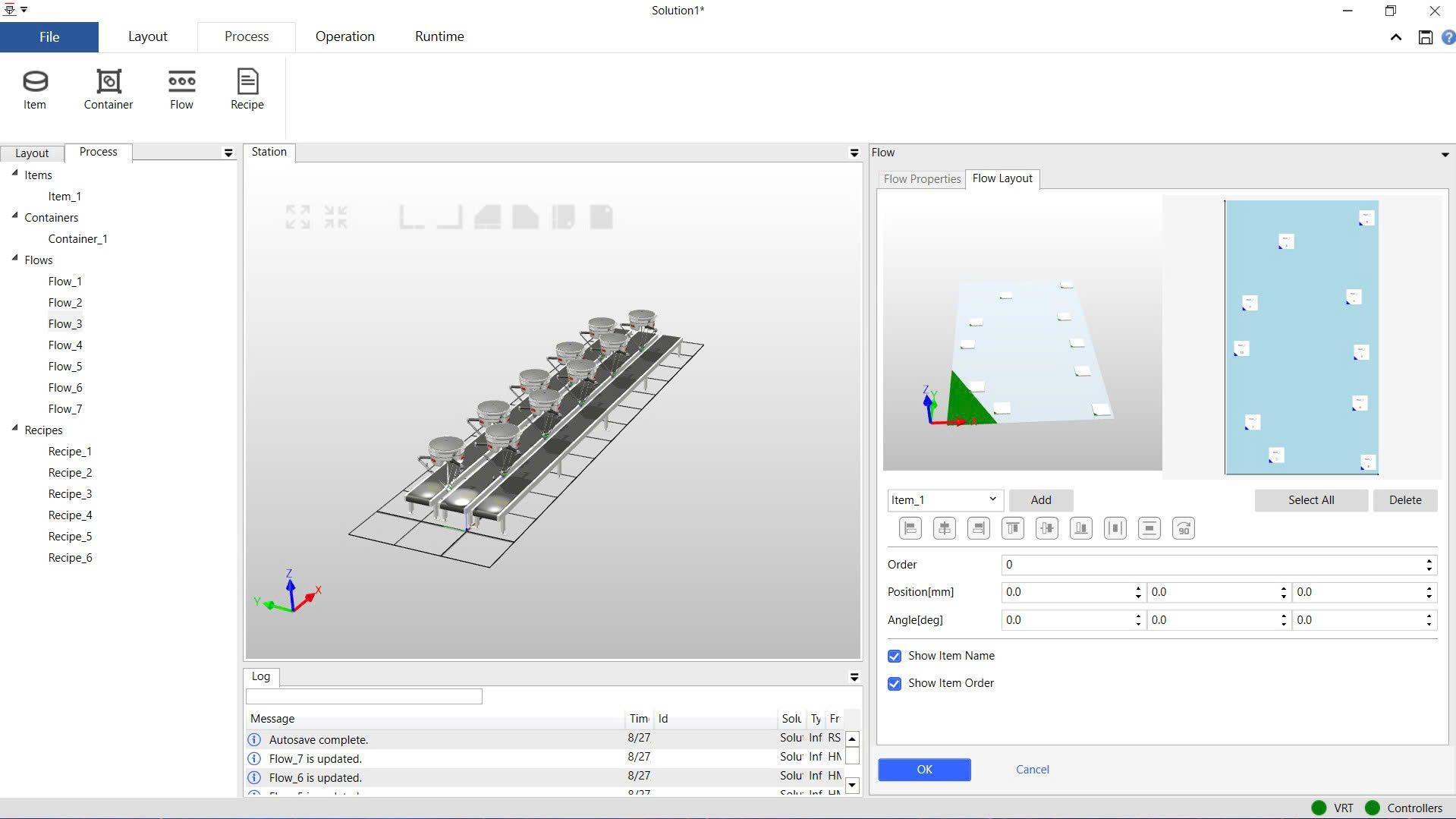

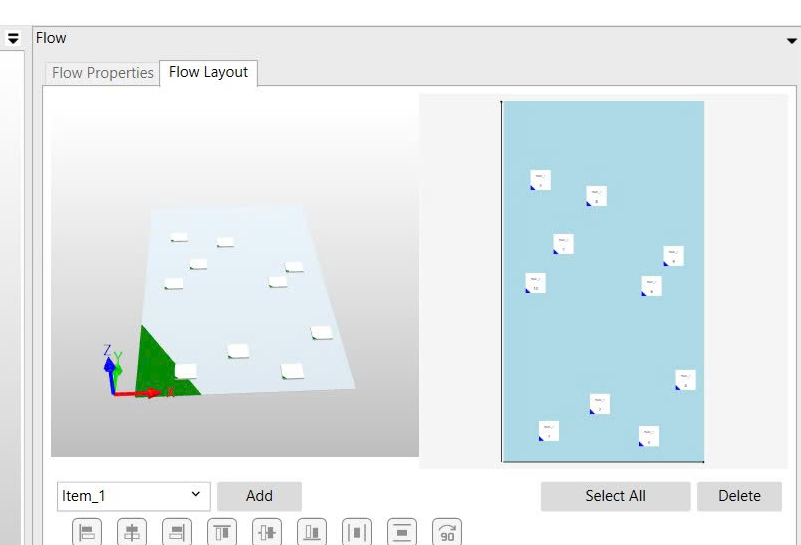

Core activities include optimizing item distribution strategies for individual robots, refining filtering and sorting mechanisms prior to execution, and embedding external camera systems and custom vision algorithms within the PickMaster Twin PowerPac framework. A comprehensive simulation and validation environment will be developed using RobotStudio and PickMaster Twin PowerPac to facilitate accurate virtual testing.

The system development will utilize ABB robotic platforms, grippers or vacuum pads, and expert technical guidance. Python will serve as the primary programming language for implementing logic modules responsible for data processing and distribution control. The use of non-ABB vision hardware will be assessed for performance compatibility and flexibility.

The anticipated outcome is a cost-efficient, modular, and high-precision robotic solution tailored to the demands of Vietnam’s emerging semiconductor sector. This integration approach aims to minimize operational latency and enhance scalability through a hybrid software-hardware architecture.