Sustainability Project - Zero Production Zero Consumption (0P0C) by Industrial Internet of Things (IIoT) and Predictive Maintenance

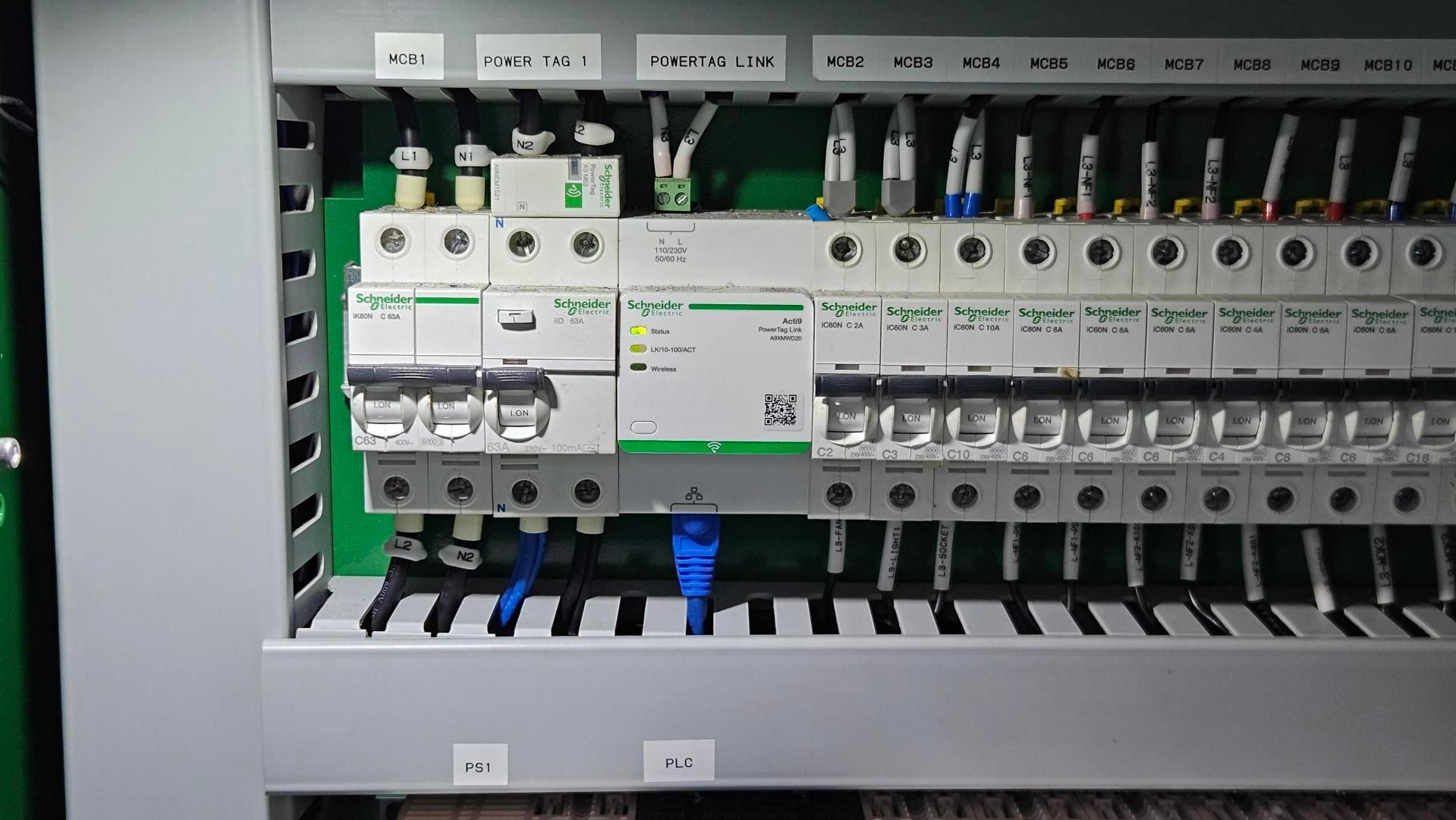

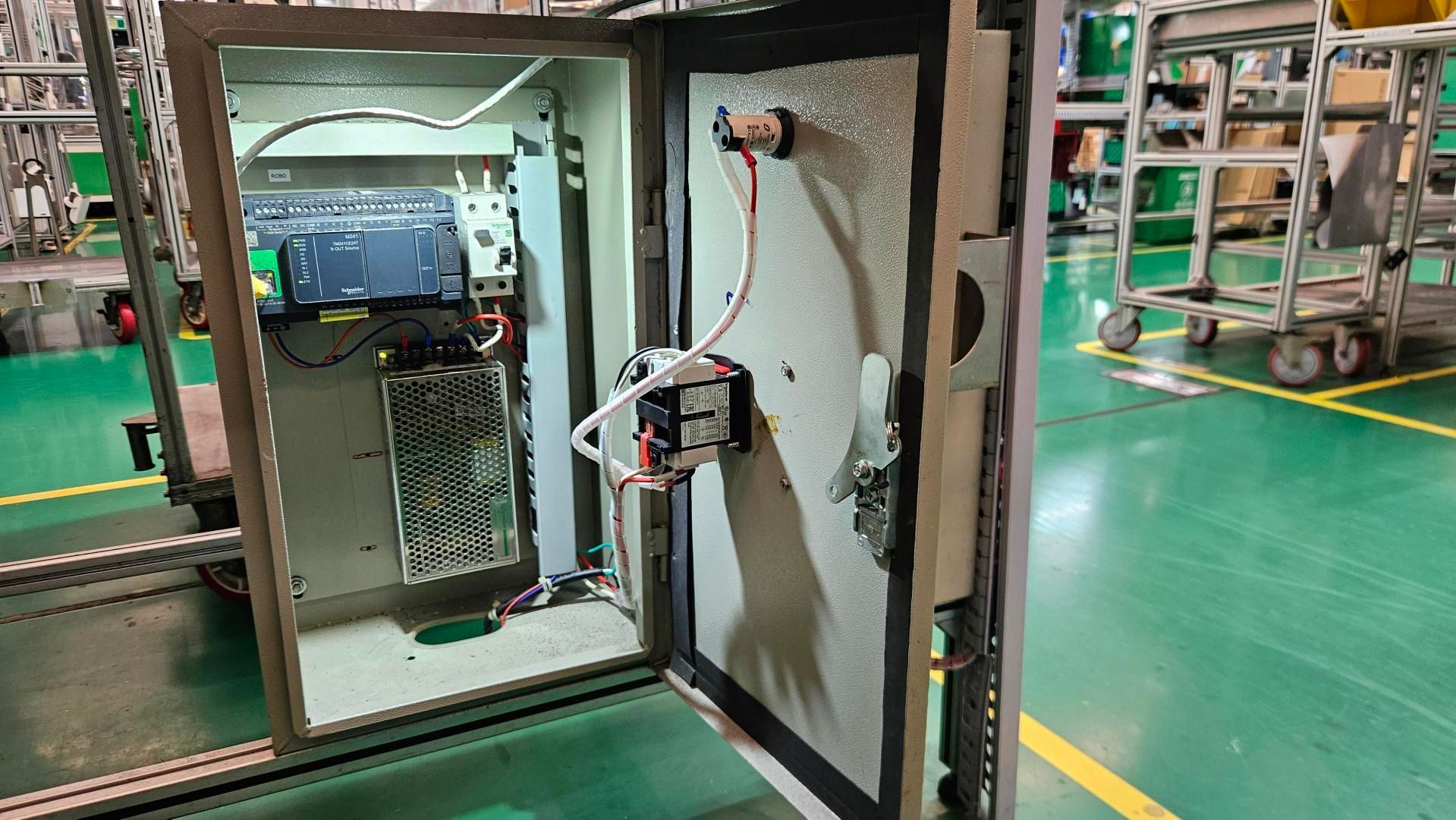

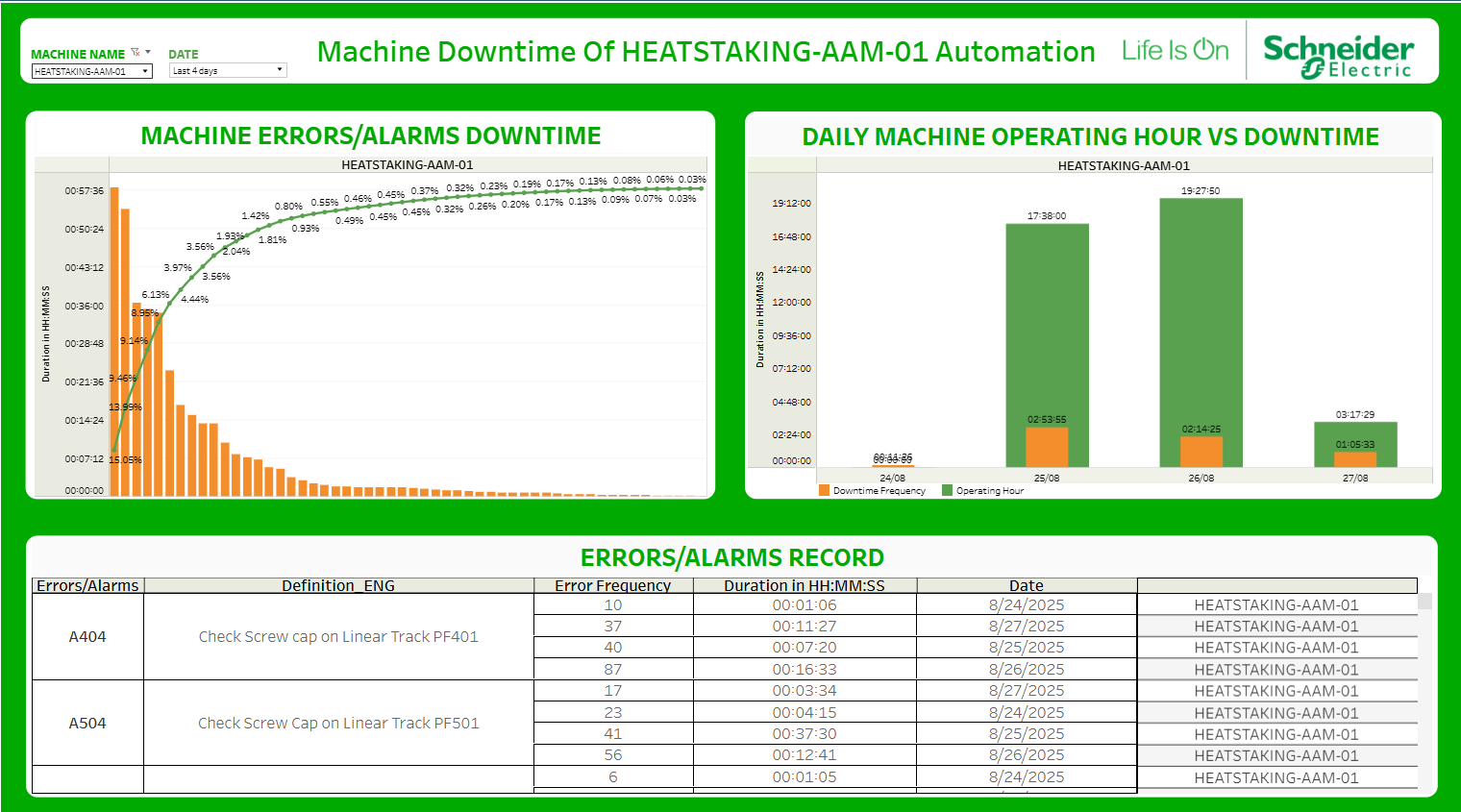

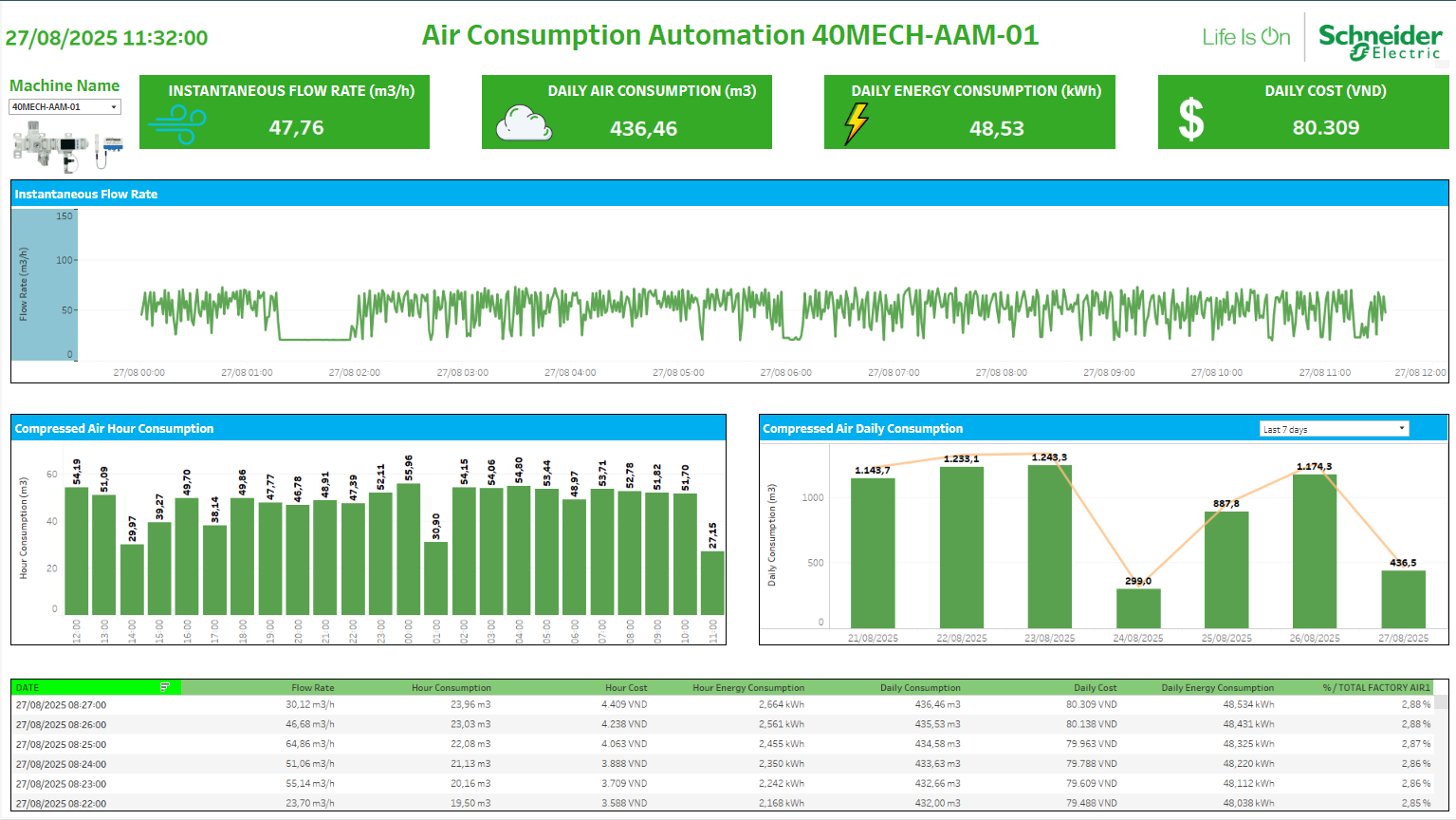

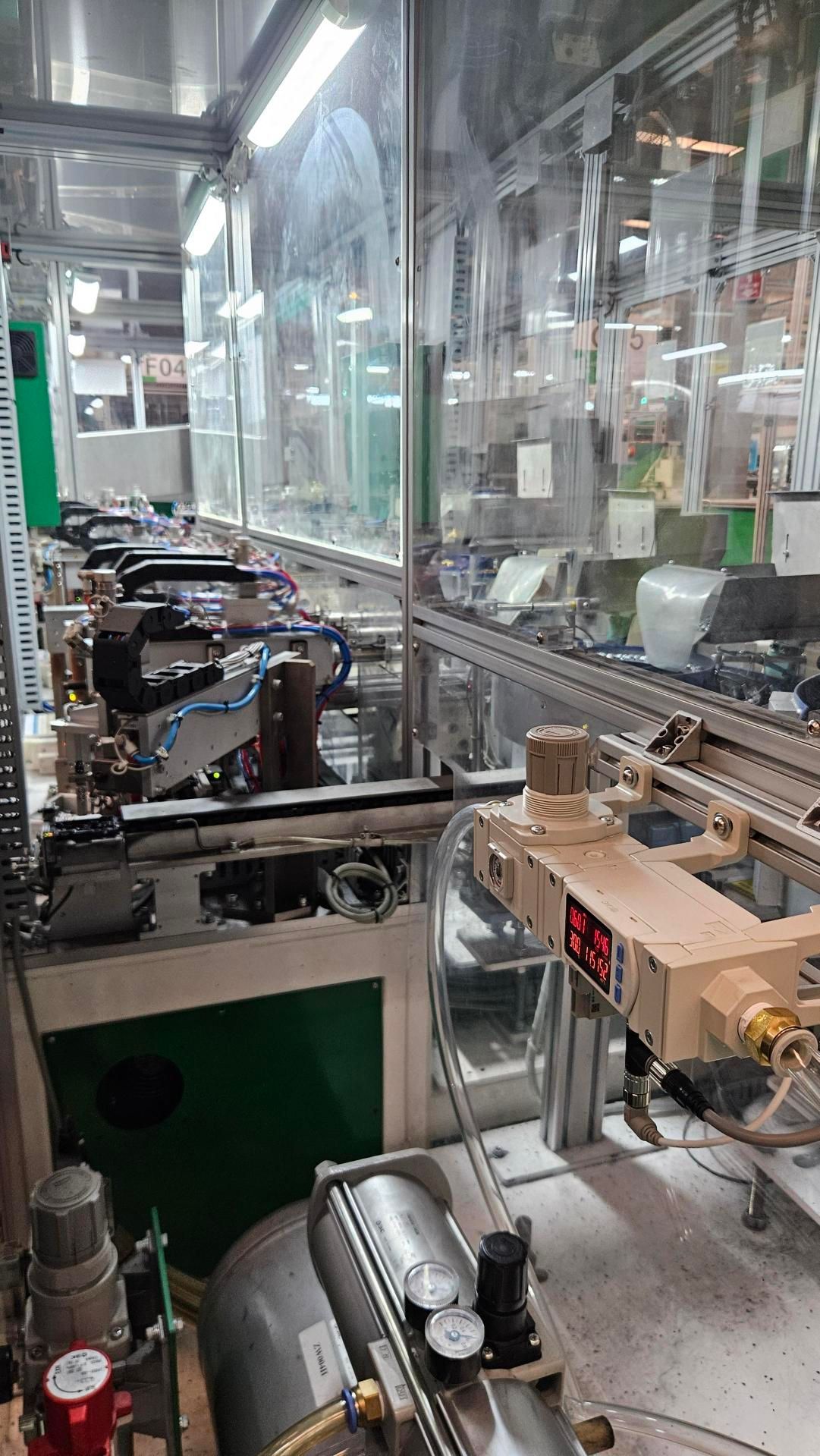

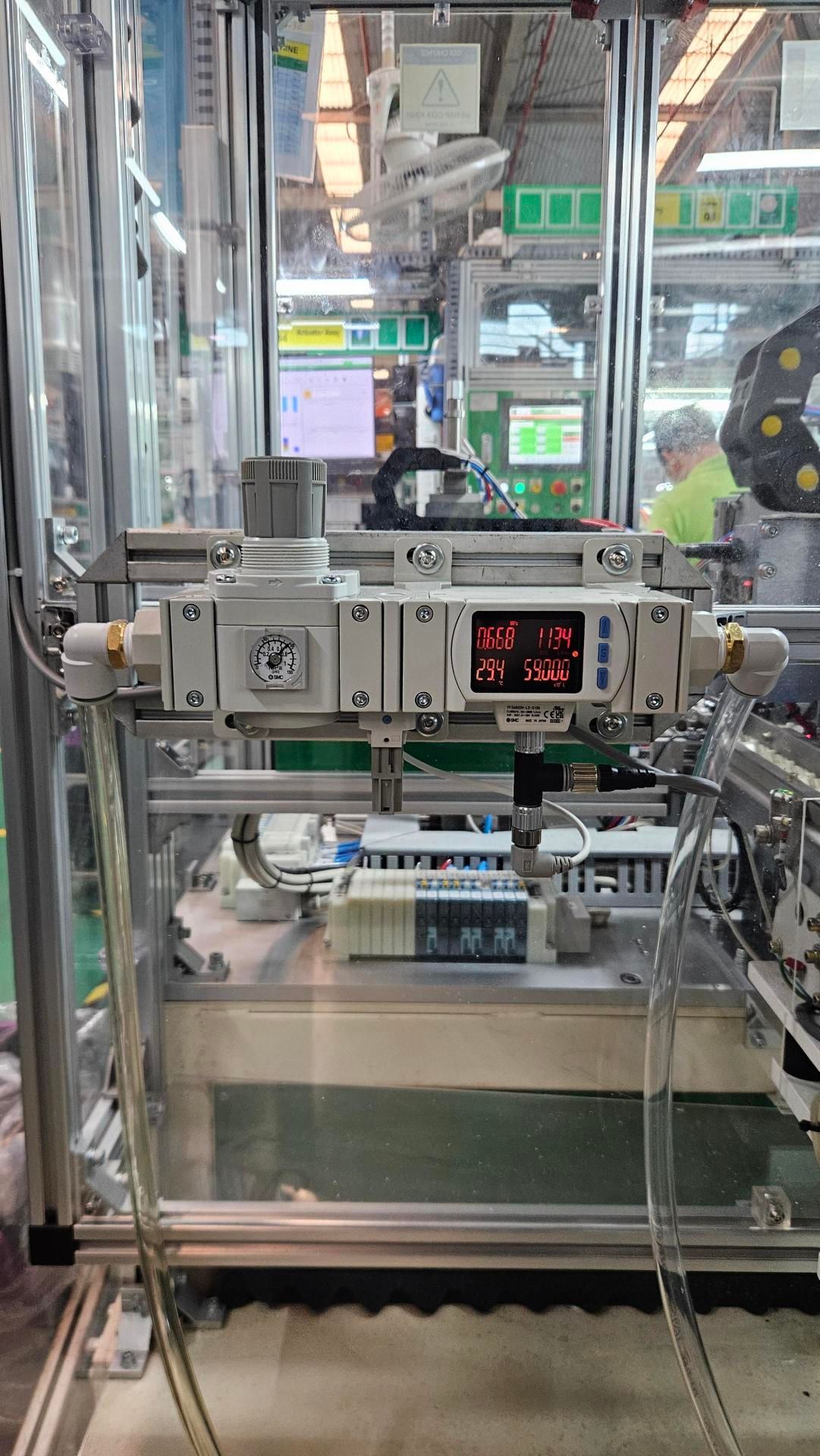

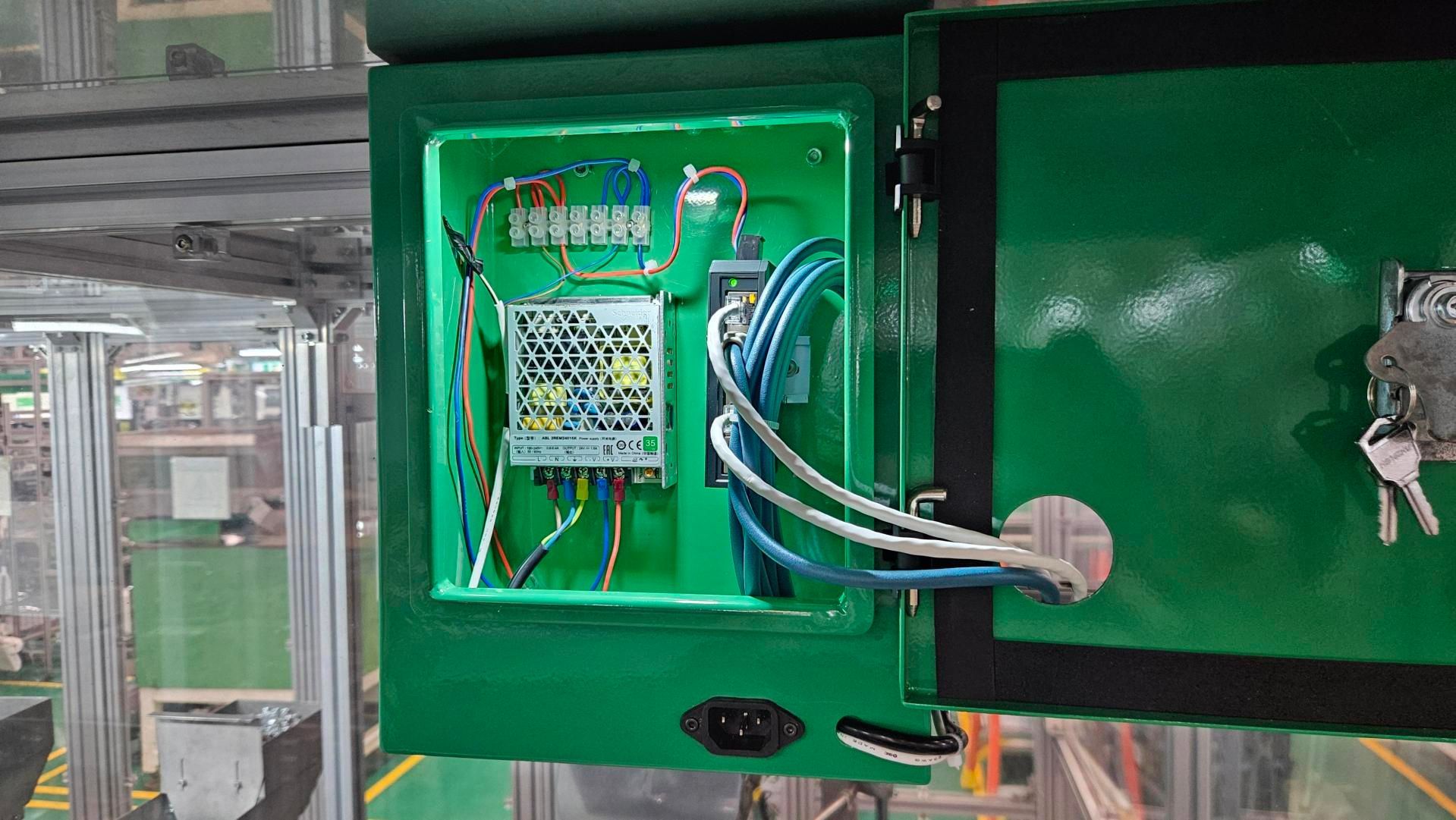

Zero Production – Zero Consumption – Gen-AI Diagnostic is an Industrial Internet of Things (IIoT) project conducted by Team ZMost from RMIT University in collaboration with Schneider Electric Manufacturing Vietnam. The project equips six critical automation machines with sensors and two PLC gateways to continuously capture energy, compressed air and machine errors. The obtained data is transferred to an SQL database and AVEVA by Node-RED and PLC gateways. Then, the dashboards created using Tableau application visualize the obtained data. This enables monitoring the energy consumption and errors of machines in a day.

Beyond visibility, we identify high energy consuming equipment, apply control logic during non-production periods to reduce waste. Information of machine errors including station, part number, brand, and type were gathered to speed troubleshooting and root-cause analysis.

Results to date show stable, reliable data capture; a 7% energy reduction on the FS-AAM-02 machine and a 3% decrease in total compressed-air consumption across the six machines. The architecture is lightweight and scalable, creating a strong foundation for predictive maintenance and Gen-AI–assisted diagnostics, with plans to extend monitoring and optimization to additional assets. By transforming consumption insights into action, the project delivers measurable savings and advances sustainable practices.