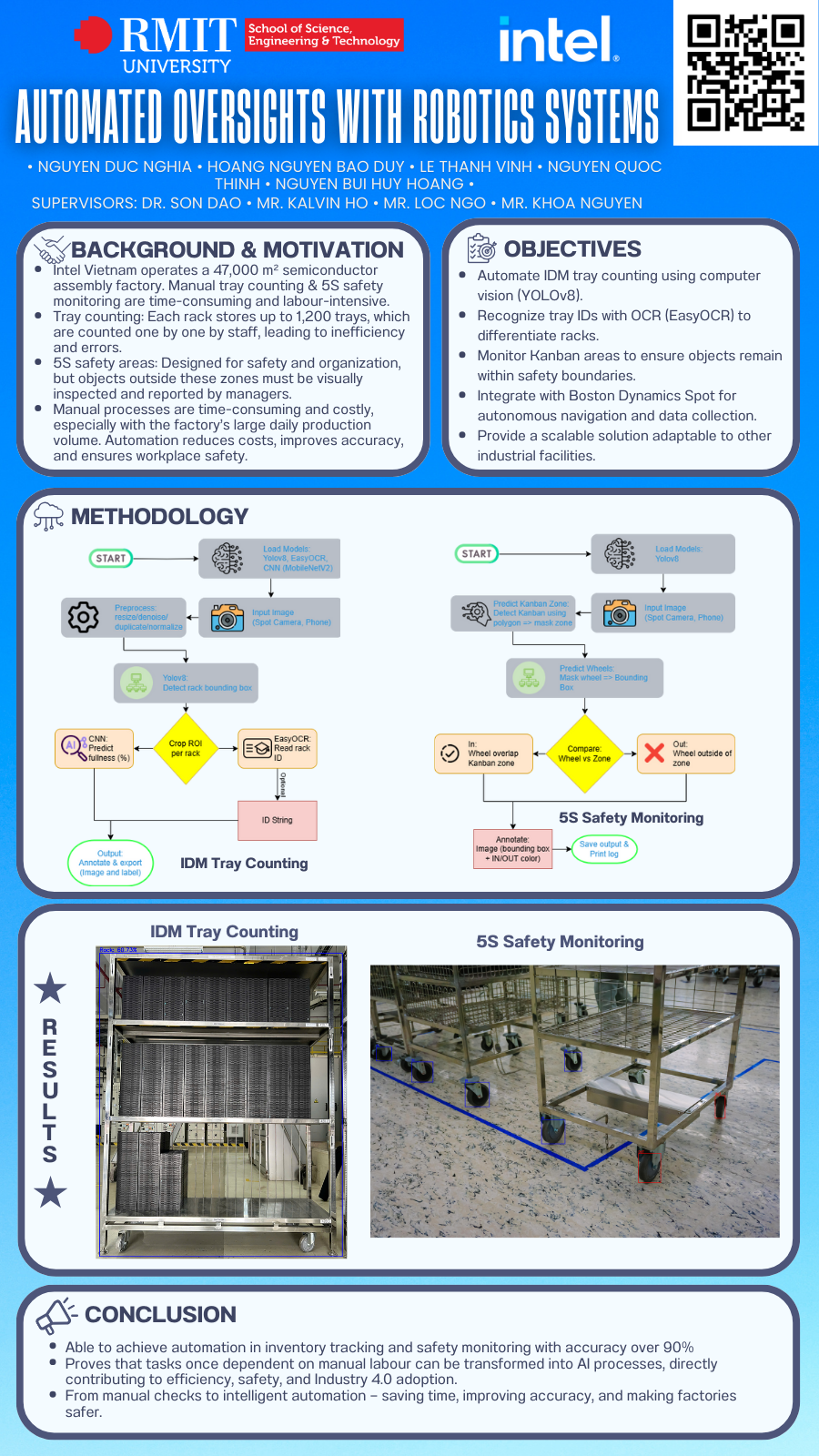

Automated Oversight with Robotic Systems

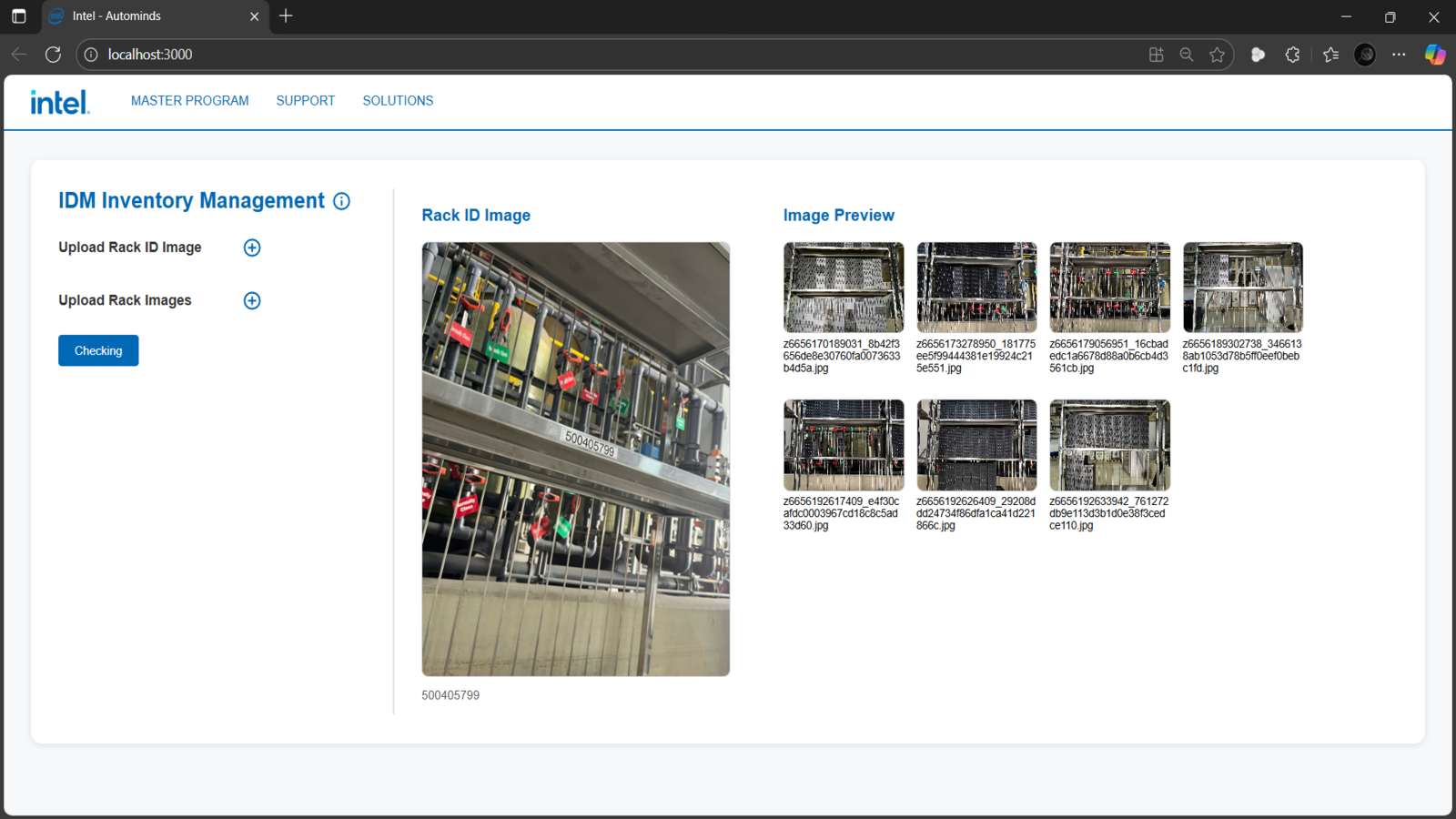

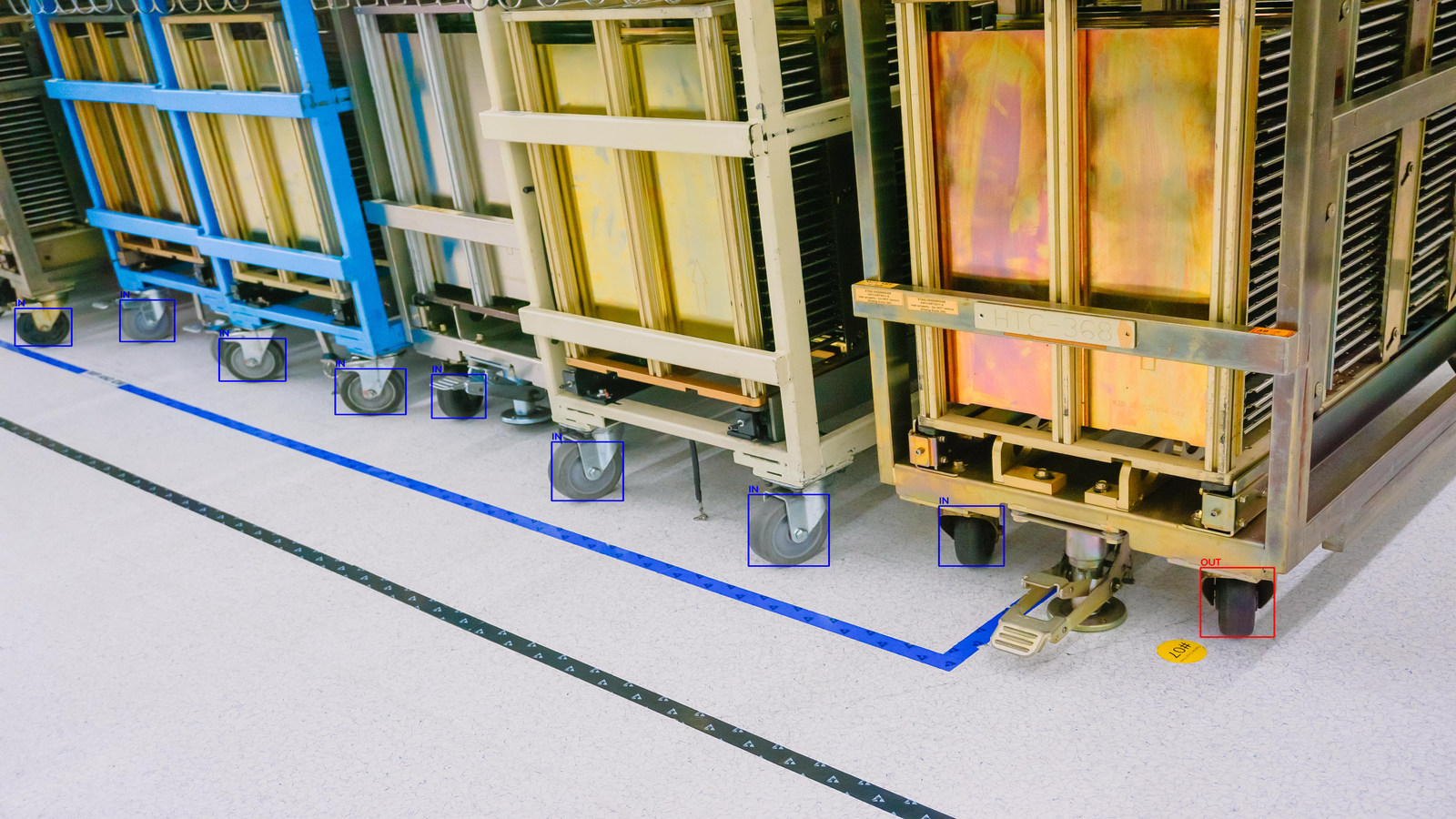

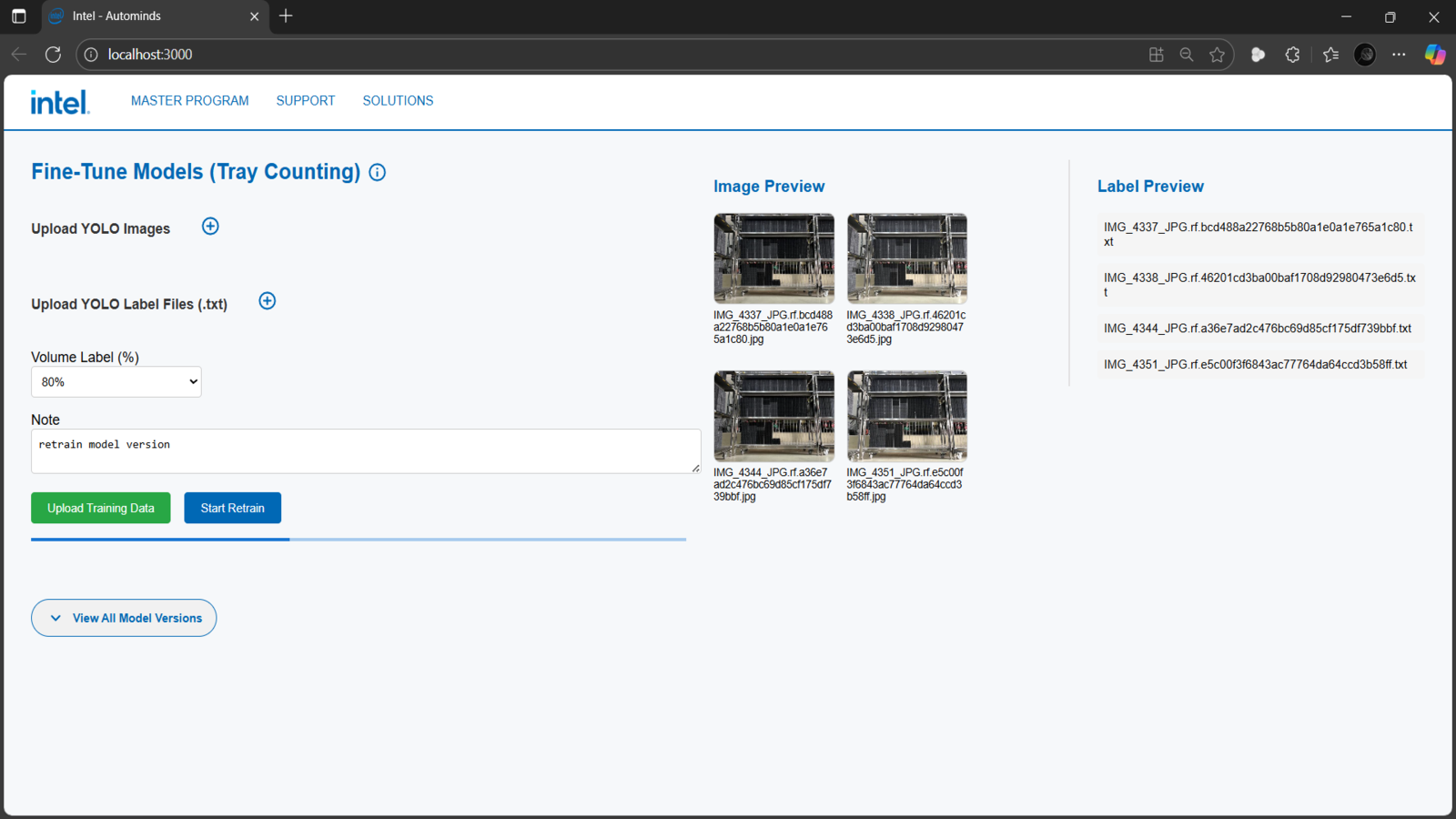

Automated oversight redefines inventory tracking in smart factories by combining robotics and AI. Using Boston Dynamics’ Spot robot, YOLOv8 for object detection, EasyOCR for text recognition, and CNN classification, the system automatically monitors the number of indirect materials and validates their positions within Kanban zones.

Why It Matters

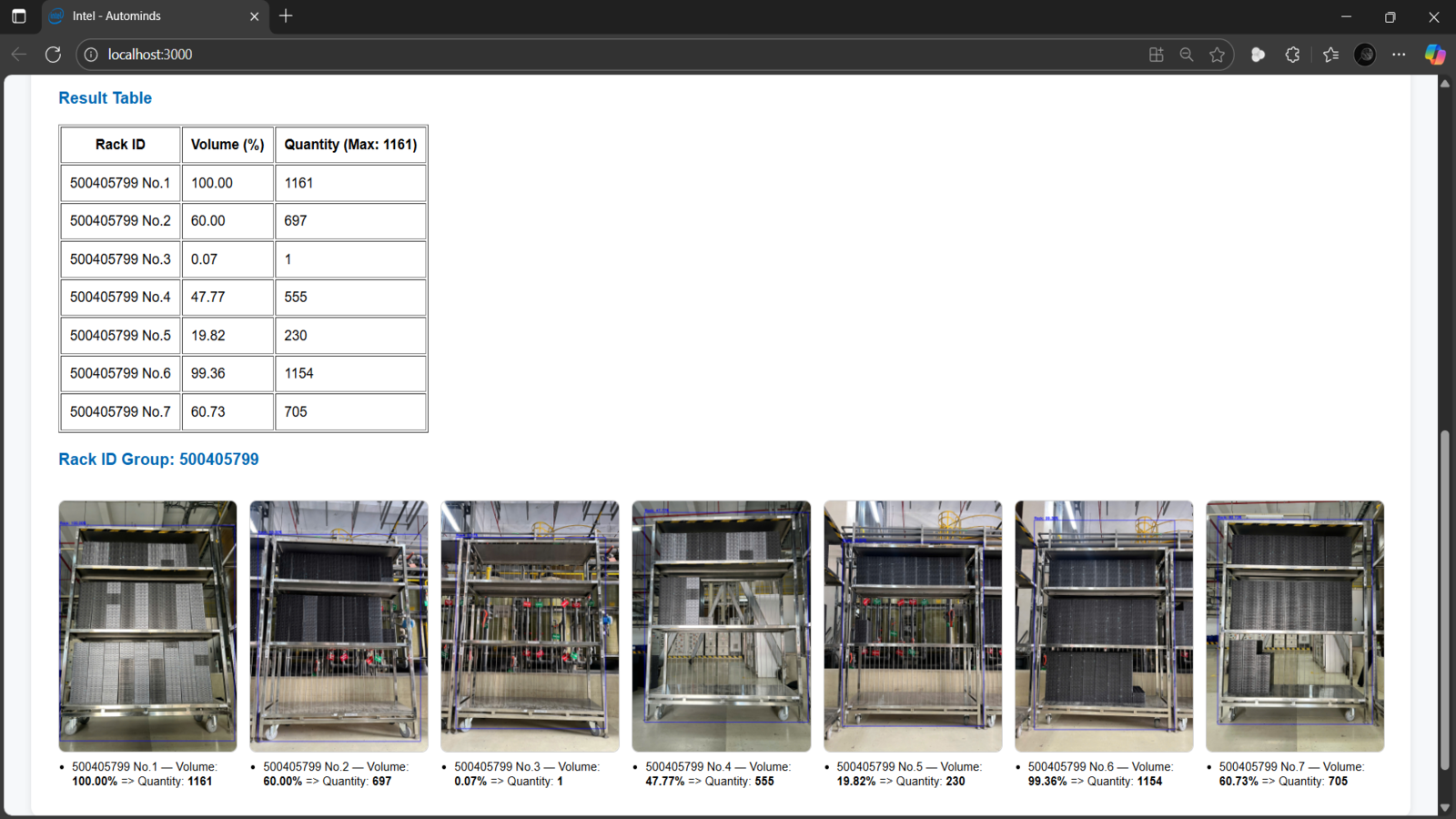

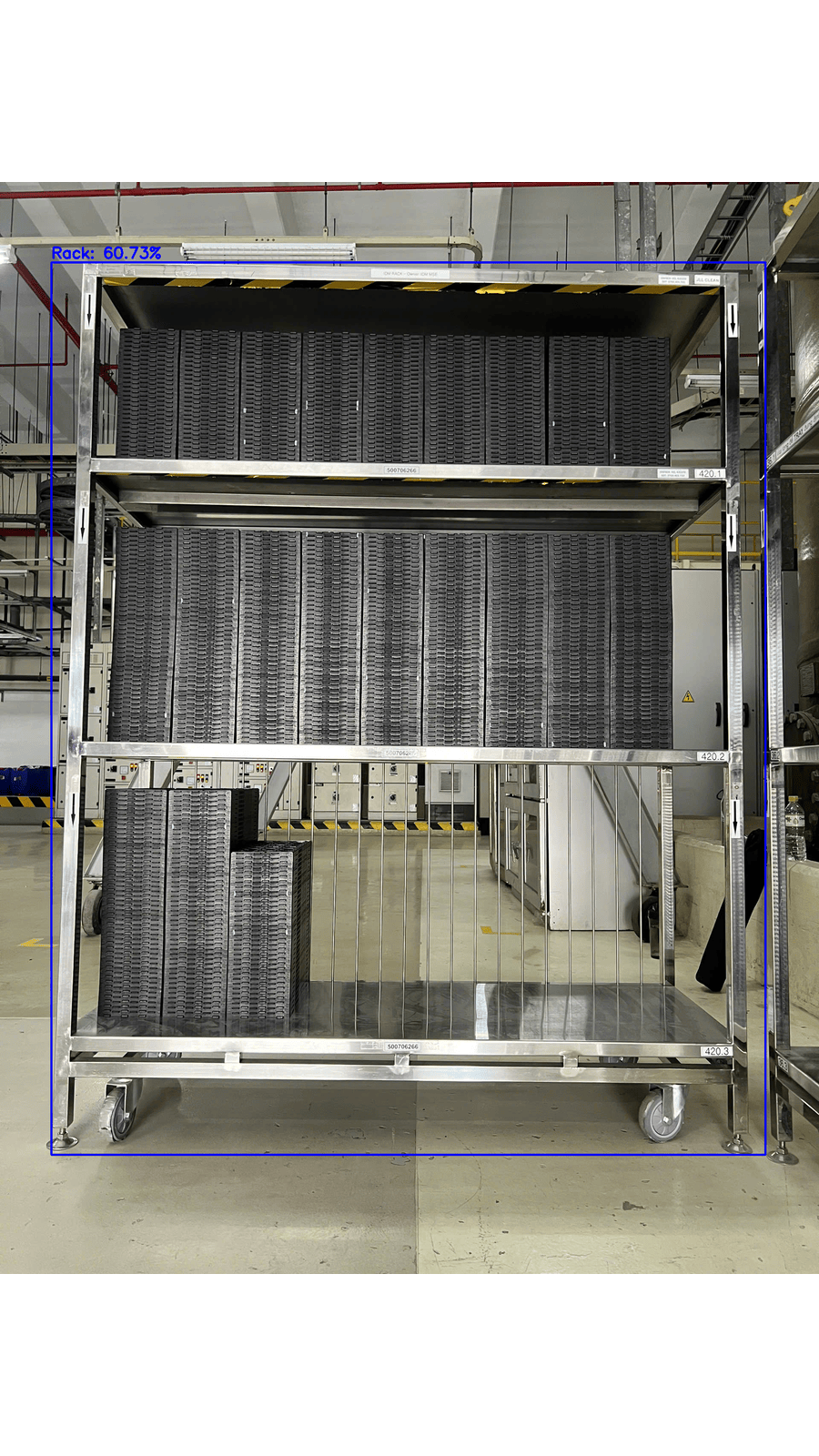

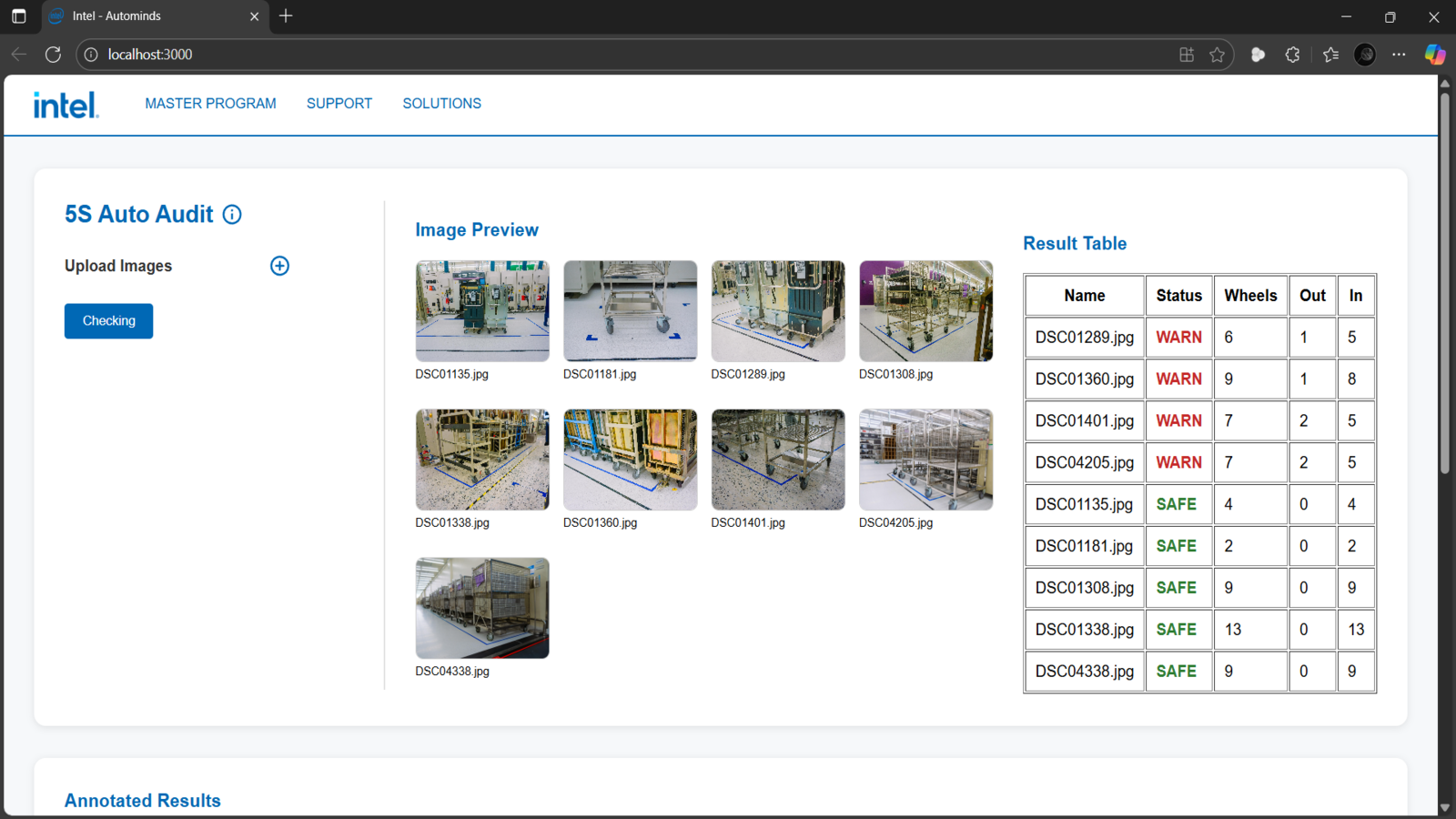

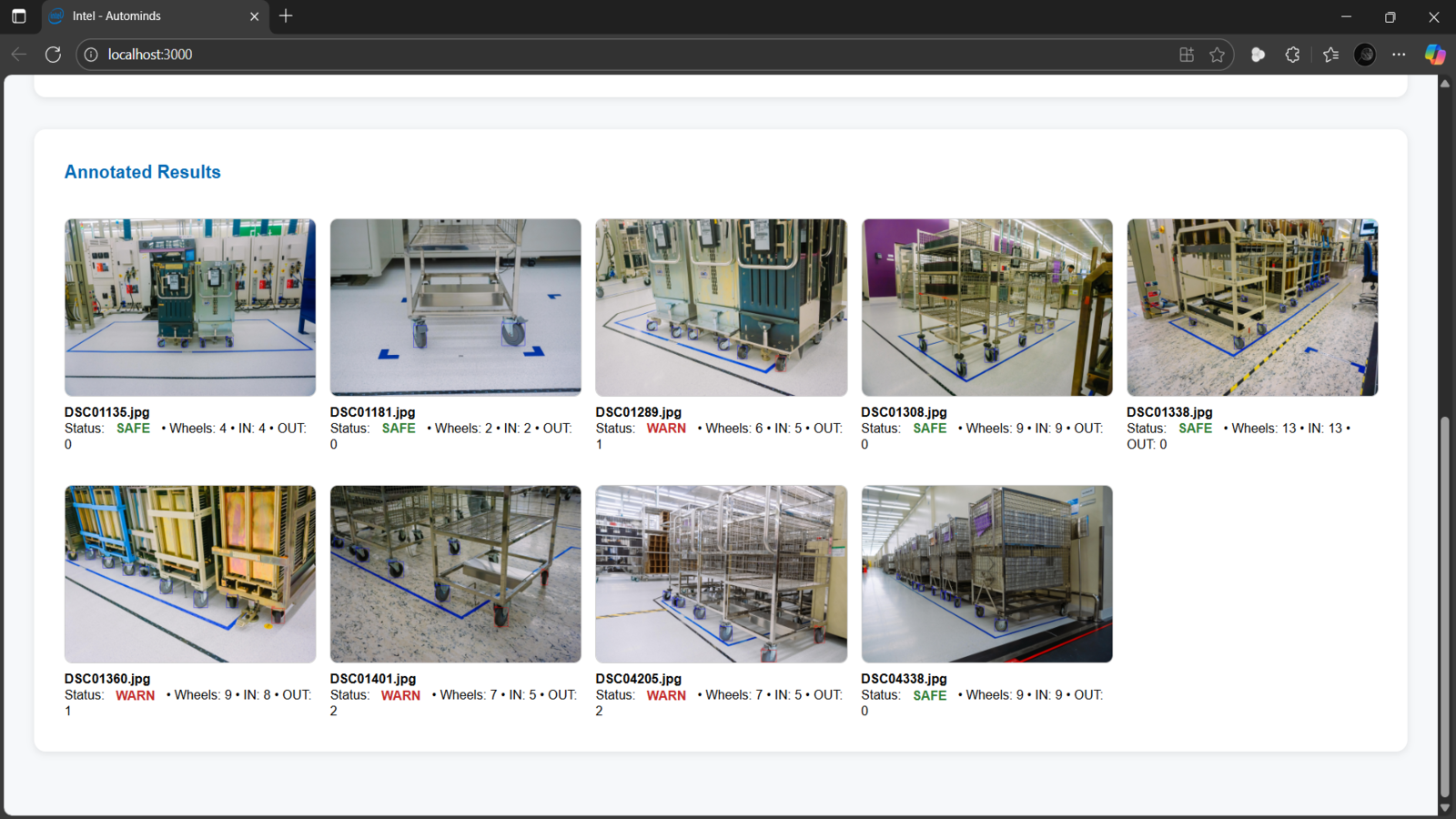

Manual inspection of trays is error-prone and inefficient, slowing down lean manufacturing processes. Our solution ensures real-time, accurate detection of available trays on the rack, the remaining space for new ones, and whether any objects have moved outside the designated Kanban zones. This reduces downtime, minimizes human error, and strengthens the 5S safety workflow in Industry 4.0 environments.

- Spot Robot Integration: Mobile, autonomous platform for flexible factory deployment

- Computer Vision Models: YOLOv8 for tray detection, EasyOCR for label reading, CNNs for classification

- Web Interface: Processes Spot’s images and displays AI model results

Our solution aims to achieve >90% detection accuracy while reducing reliance on manual checks, paving the way for fully automated quality assurance in manufacturing.