Mixed Case Palletizing System with ABB Robot

Hasindu Kaveesha Dewasurendra

Saumith Udula Gonapaladeniya

Nguyen Le

Utkarsh Sarbah

The existing warehouse and distribution structures cannot keep up with the increased volumes of good flow following the recent growth in the e-commerce industry. While the front-end of the consumer network: online shopping platforms and retail sites have been successful to host a large customer base, backend inventory management remains a potential field for engineering innovation.

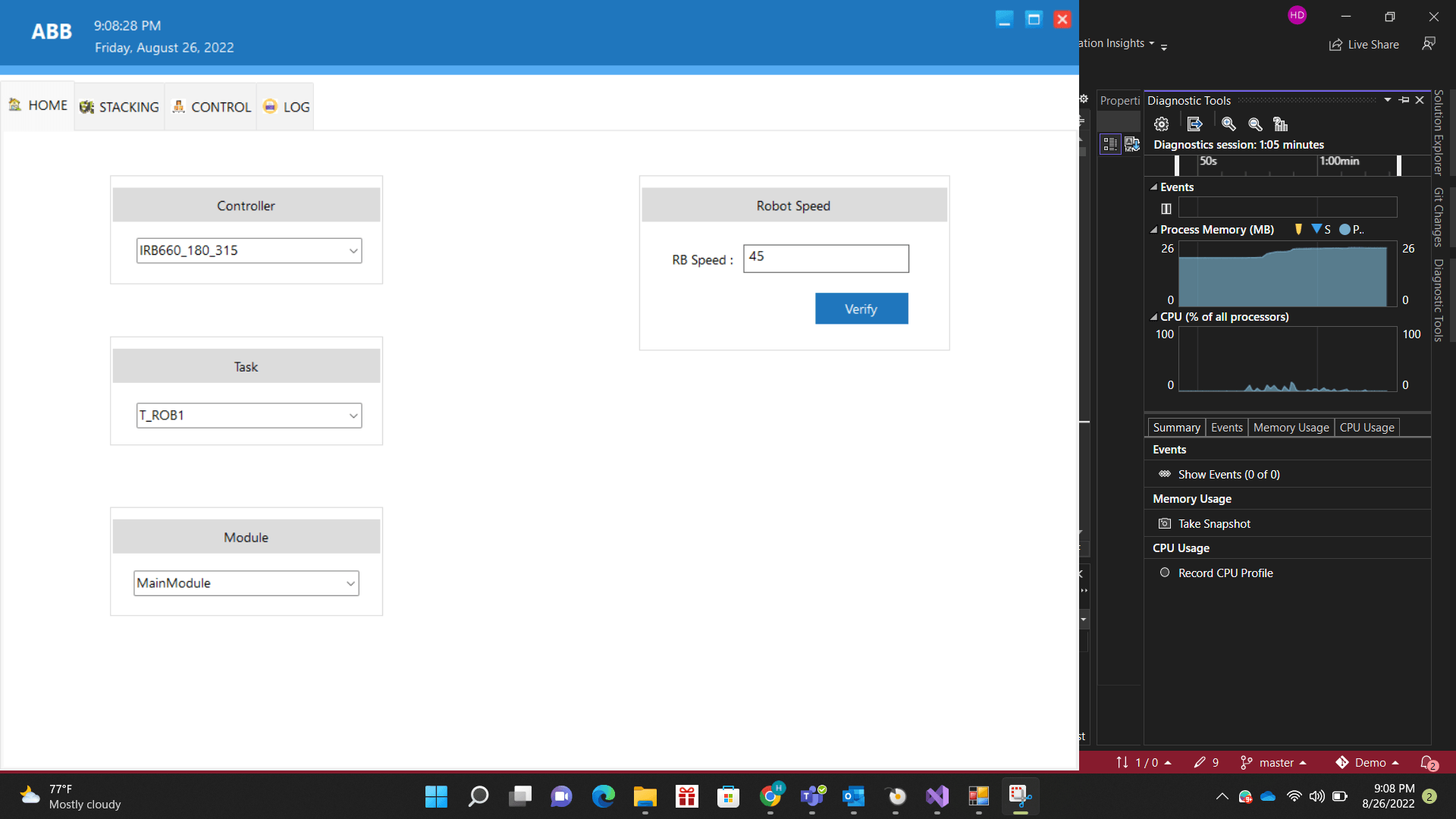

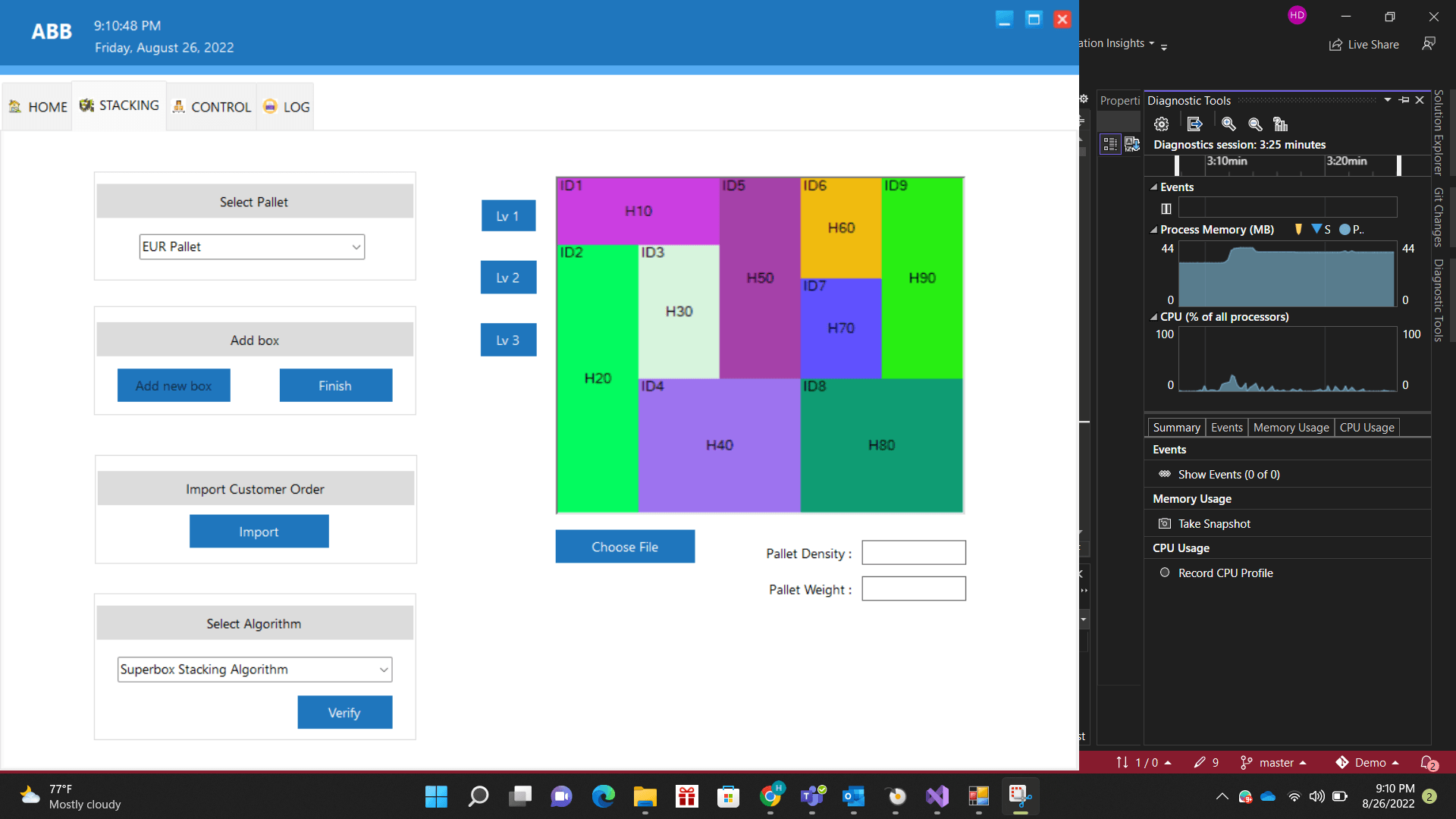

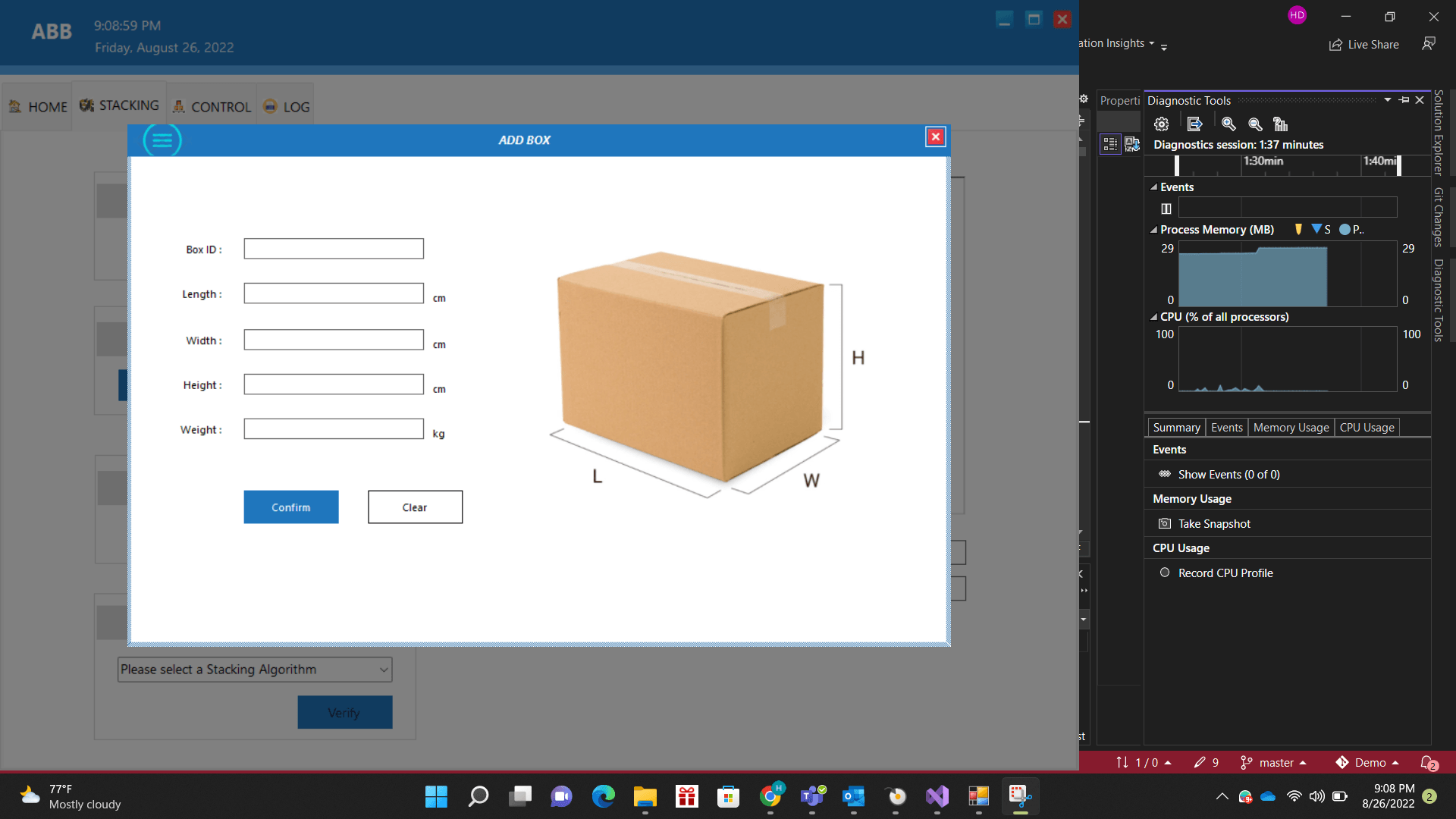

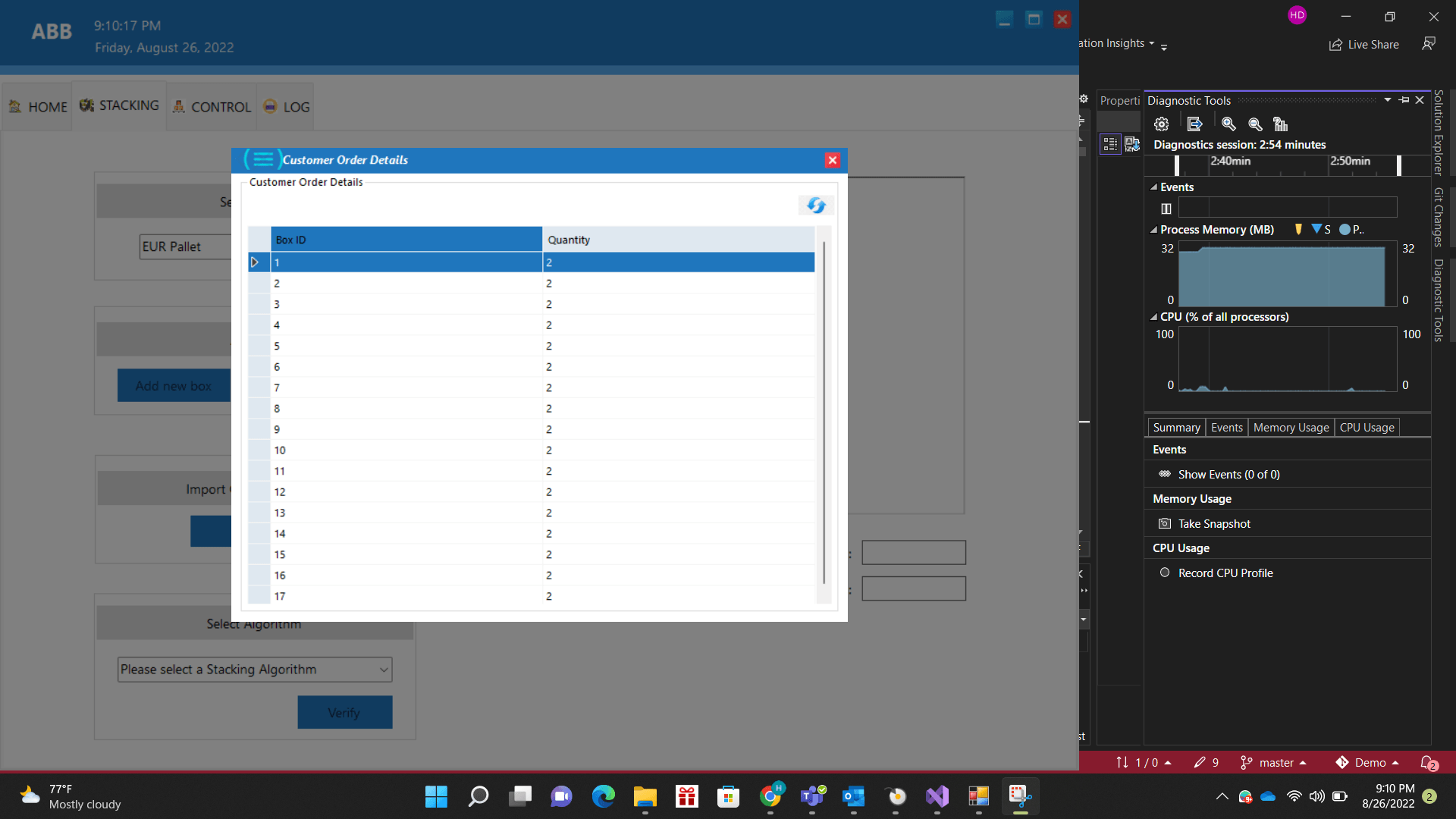

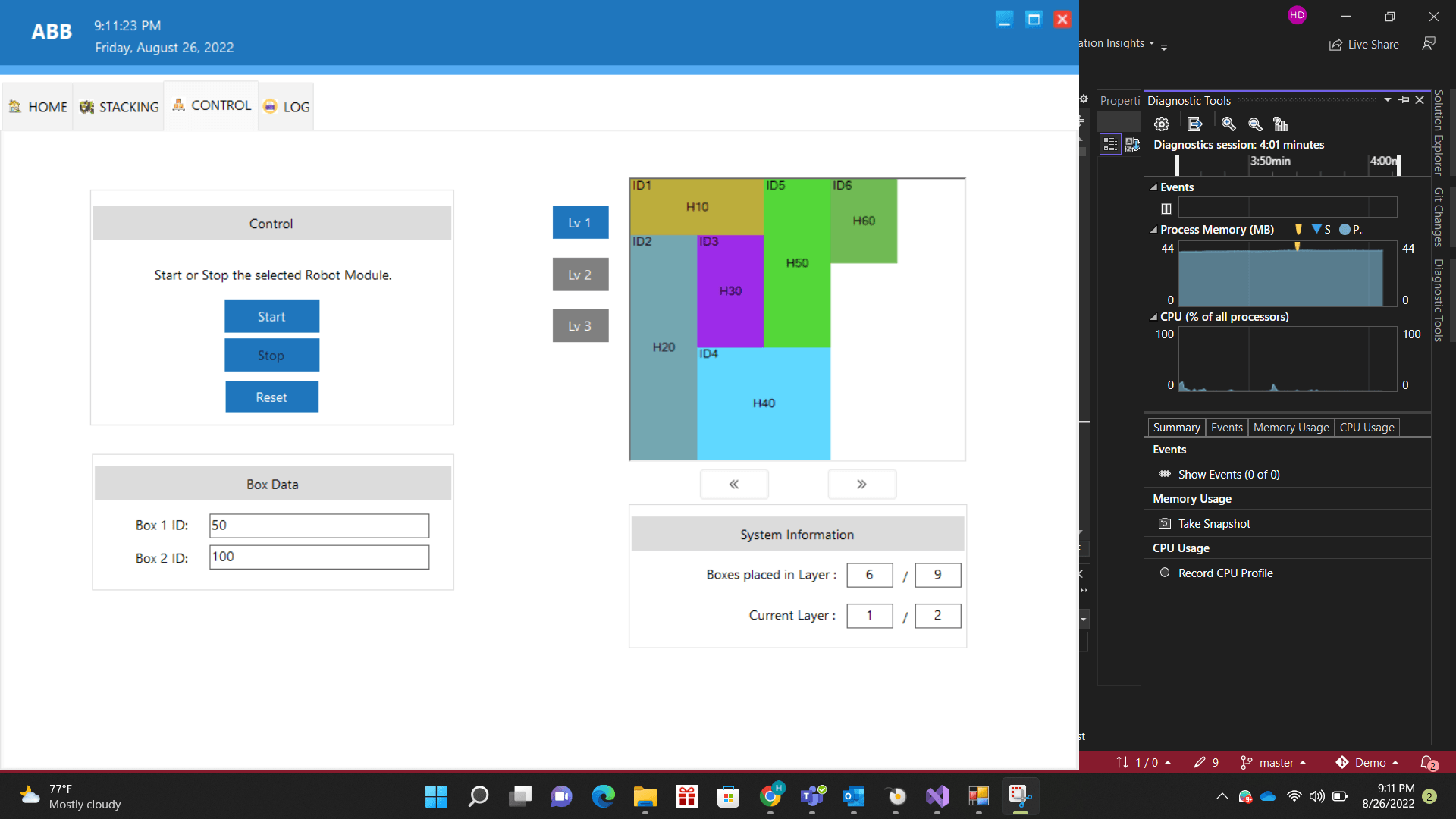

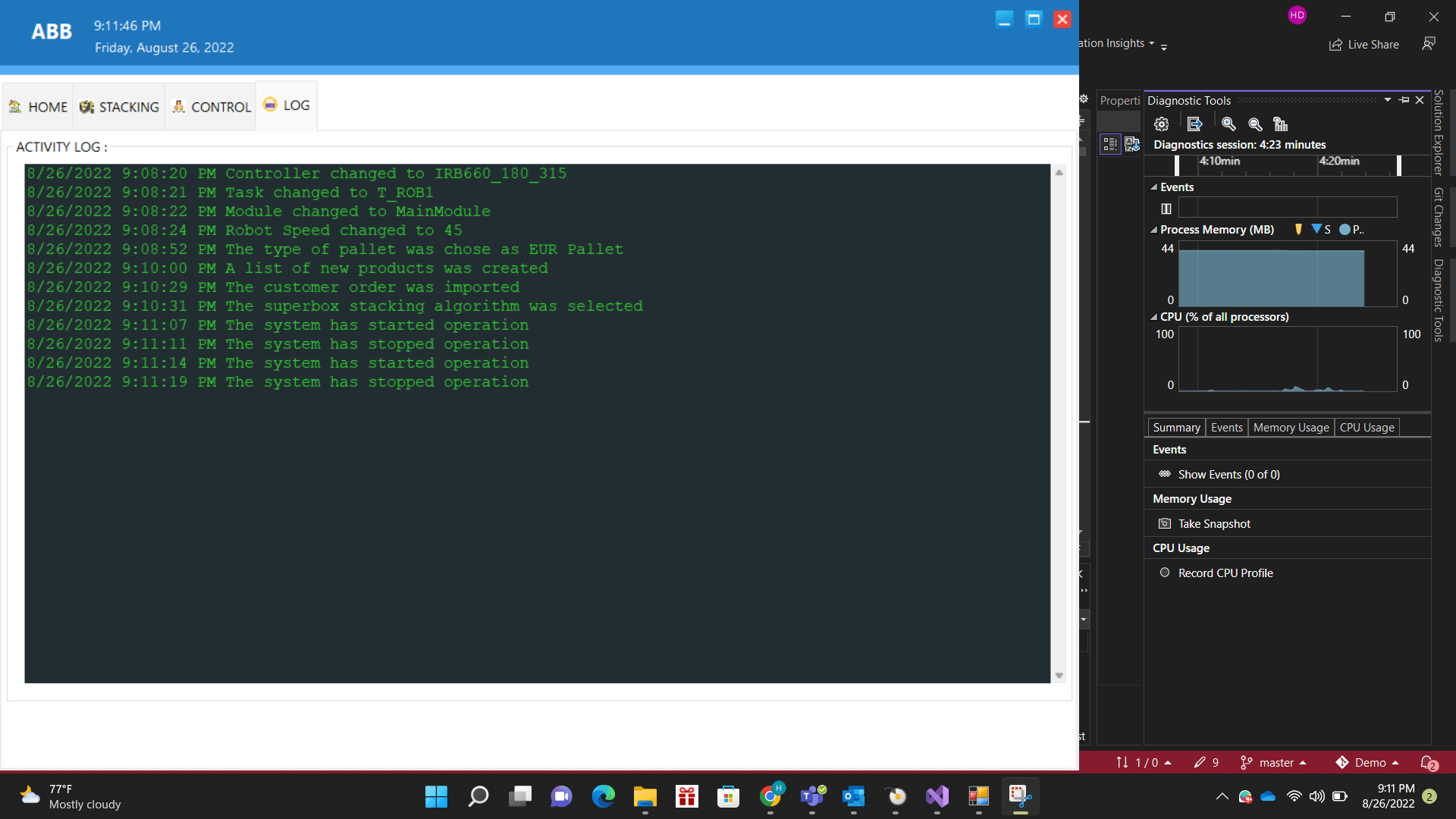

To this end, RMIT Capstone students from team ‘The Eccentrics’ has collaborated with ABB Vietnam to develop a mixed case palletizing system which makes use of the industrial robot ‘IRB660’ to automate the process of palletizing in warehouses and other storage facilities. Mixed case palletizing is a process where stock-keeping units (SKU) of different dimensions and properties are arranged on a pallet to achieve the highest possible pallet density and support. Earlier, palletizing was performed manually, and the products had to be sorted, transferred, and stacked by the hand of human operators which was inefficient and always done at the risk of injury. The automated palletizing system (APS) is designed in place of manual labor as a more efficient, safer, and economical solution to meet the industry standards of ABB and cater to the demands of clients like Coca-Cola and Nestle. Considering the scope of this project, our team was responsible for developing the stacking algorithm which provides the optimum arrangement of products on a pallet and the UI for interfacing and monitoring the system. Summarising the operation of our solution, we first choose a specific robot module and configure the initial data for the system. Next, we import the customer order (a list of products to be packed) and choose the stacking algorithm through the UI. After confirming the pallet layout by a 2D image, the operation can be started or stopped using the different control options from the UI. With previous systems achieving promising results of 80% consistent placing, 84% average packing density and 99% fully supported pallets, we believe APS can be the change needed in the logistics industry.

The design solution was thoroughly tested using a series of test cases and unit testing was done on the individual features of the UI to ensure that the quality of the delivered final product satisfies our standards. In conclusion, addressing this problem and coming up with a customized APS gives ABB early access to a market with huge potential with as limited as 10 mainstream competitors revealed in a market study in 2015.

Demo Video