Application of Computer Vision and Robotic Arm in Cashew Nuts Production Line

Tran Hoang Nam

Tran Nguyen Quang Minh

Hoang Van Phuc Trieu

Vu Duy Khoi

Together with the Forth Industrial Revolution, our team aims to provide the solution that utilizes the advantage of automatic technology to local Vietnam enterprise and maximize the profitability from the era of automation. The context of this project focuses on the local cashew nut factory, where most of the processes rely on labors’ workmanship and skills, not to mention the short-term labor and the time needed to provide proper training.

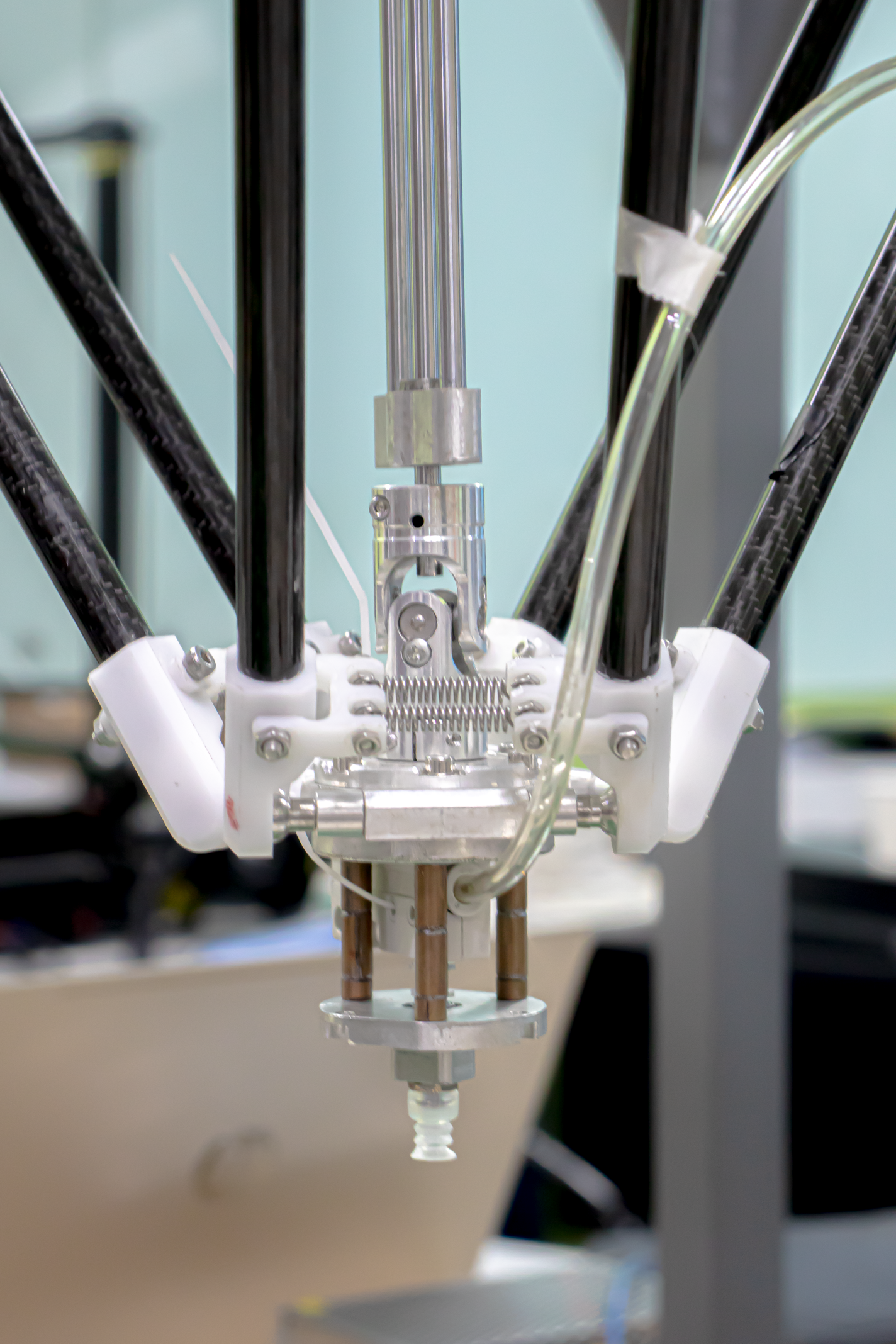

Hence, this project aims to automatize the quality control (QC) line of the cashew nut production process by implements the application of Computer Vision technology to self-detect faulted cashew nuts and have it removed automatically using the Robot Arm. The Computer Vision System is equipped with the Basler Ace 2 camera that includes state-of-the-art CMOS sensor technology, allowing great compatibility with multiple Computer Vision application at an industry level. Moreover, the crux of the system relies on one of the most high-speed, high-accuracy detection algorithms – the You Only Look Once (YOLO) 4th version. Nonetheless, the pick-and-place process to remove the defected cashew nuts is manipulated using a four-degree-of-freedom Delta Robot, equipped with an external pneumatic logic control (PLC) system.

Demo Video