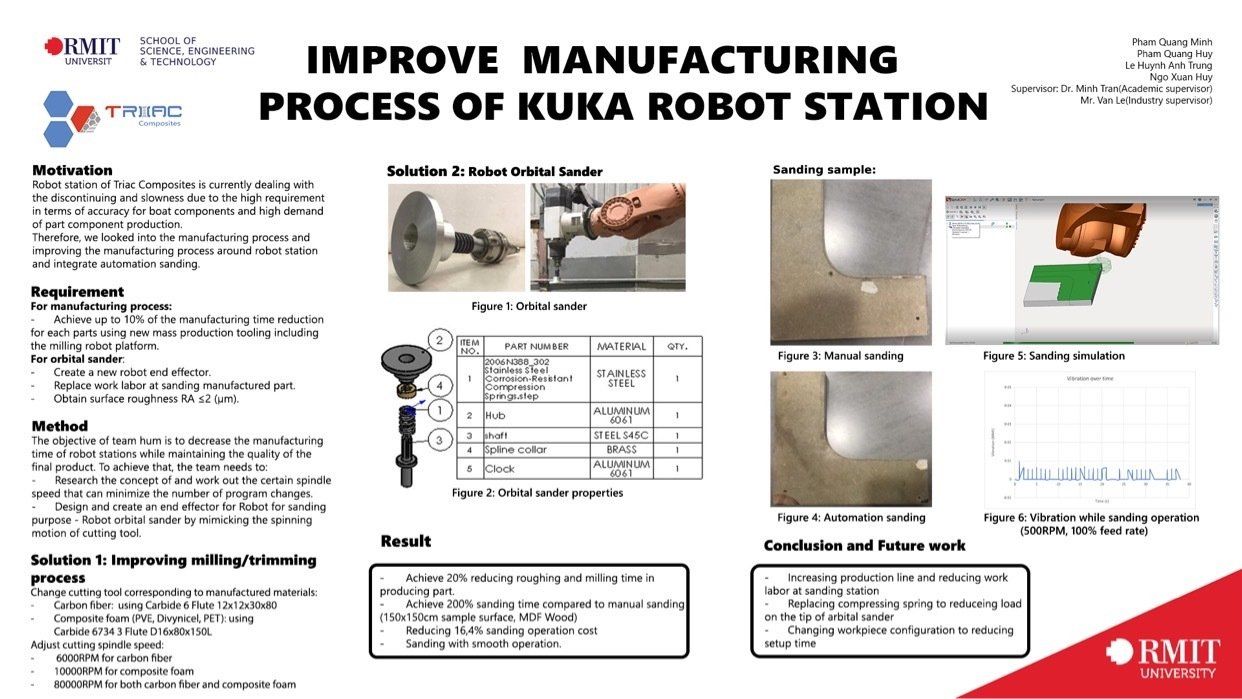

Improve manufacturing process of KUKA robot station

Pham Quang Huy

Pham Quang Minh

Ngo Xuan Huy

Le Huynh Anh Trung

Technology is progressing in the same way as human wants are fast expanding. Every day, the effort to address these objectives makes life more accessible, and the research focuses on robotics. Today, scientists have recently used the term "Robot" to describe any artificial machine capable of performing a job or other action generally performed by a human, either automatically or via remote control. Far from the universality of this robot, because it is the accuracy of work and performing it for humans, robots have become one of the most frequent things that scientists are still working hard to improve. As a result, robot arms are frequently used in factories; Triac Composite is a good example. In this project, we work with Triac Composite company to improve their robot system efficiency and accuracy. In the process of working with Robot Arm Kuka, we realised the problems that we need to solve are:

- Improving the manufacturing process:

By focusing on the company process of producing one boat component, a profound analysis each step will help the improvement process. Furthermore, the team can compare to the standard industrial manufacturing process to find the weakness (time-consuming, redundant steps).

- Orbital sander manipulator integration:

The company worker has manually done this step. In the composite working environment, the sanding and polishing work is usually heavy work and dusty. This work can be hazardous for the workers since they are continuously exposed to the dust of composite materials such as resin, foam, and fiber. The solution is to implement an automation sander at the robot station.

Demo Video