Automated algorithm

to optimize delivery schedule at Unilever factory

Diep The Thinh

Nguyen Dang Quang

Nguyen Danh Duc

Duong Huu Khoi

Unilever is a multinational company that produces consumer goods. In Vietnam, Unilever has a manufacturing factory in Cu Chi, with 4 production plants: Home Care Liquid (HCL), Personal Care Liquid (PCL), Oral Care, and Food. The HCL plant has a higher rate of production than the rest, so there is a large number of material deliveries per day, which leads to problems during deliveries and unloading in the warehouse.

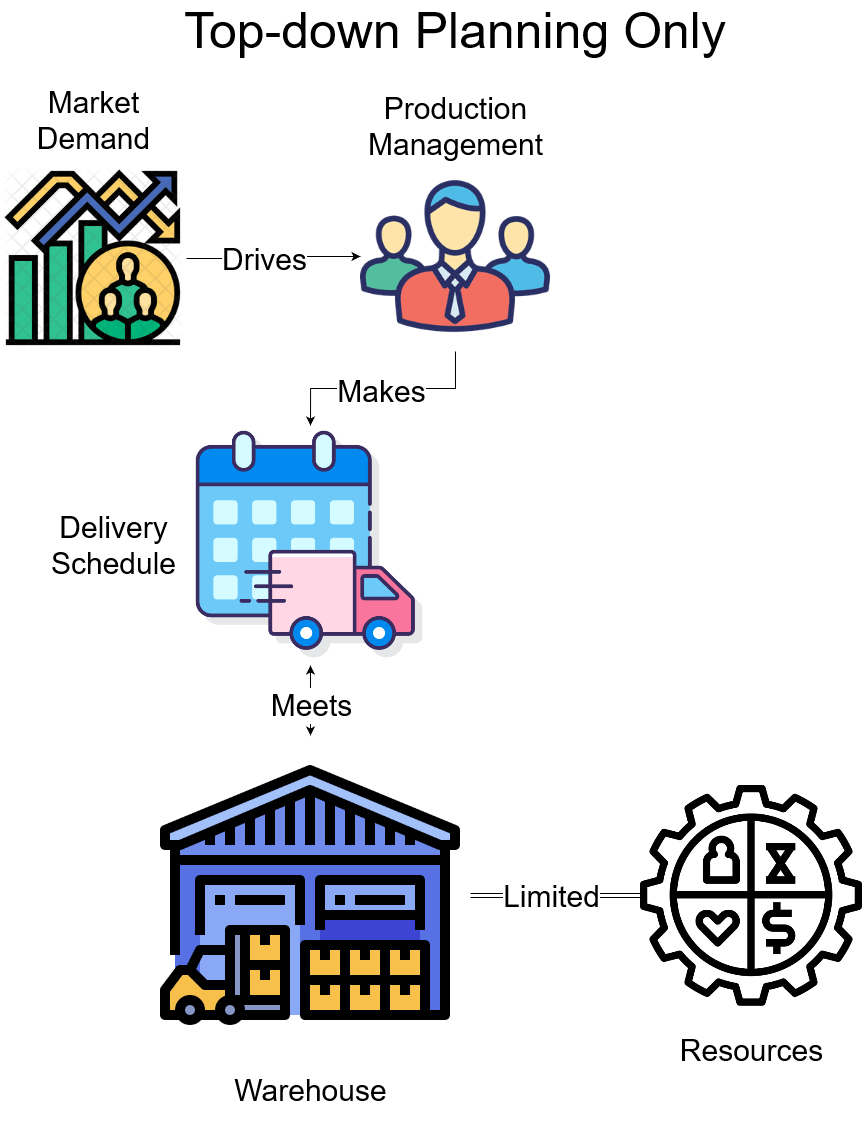

The current Delivery Schedules (DS) that the plant utilizes to organize deliveries are made by the production team, who try to meet the market demand. As such, it does not account for the capabilities of the warehouse workers to deliver and unload the materials. As a result, there have been cases where deliveries have been delayed because of previous incomplete deliveries and competition for warehouse resources by different suppliers.

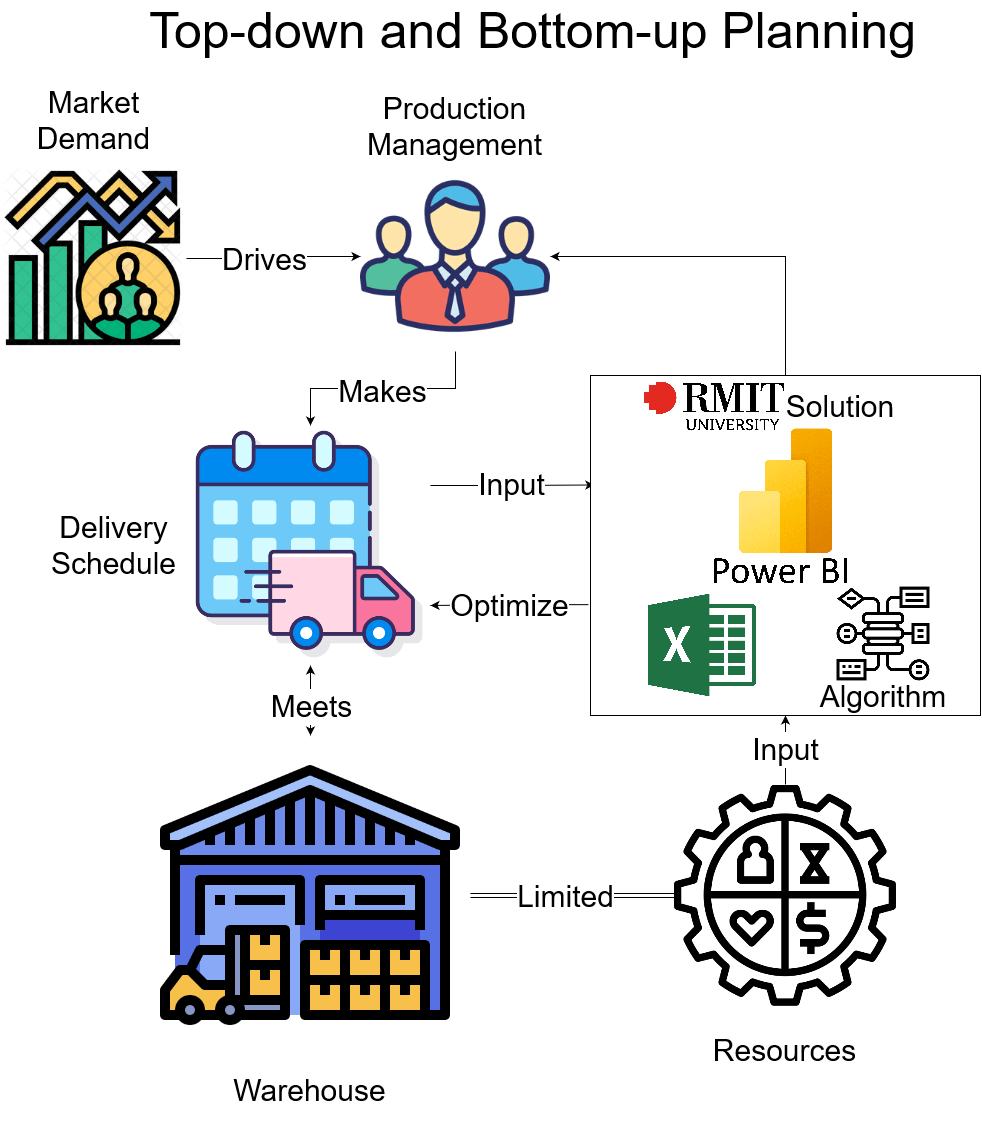

The project's goal is to visualize and optimize Delivery Schedule at high-volume HCL warehouse of Unilever Factory.

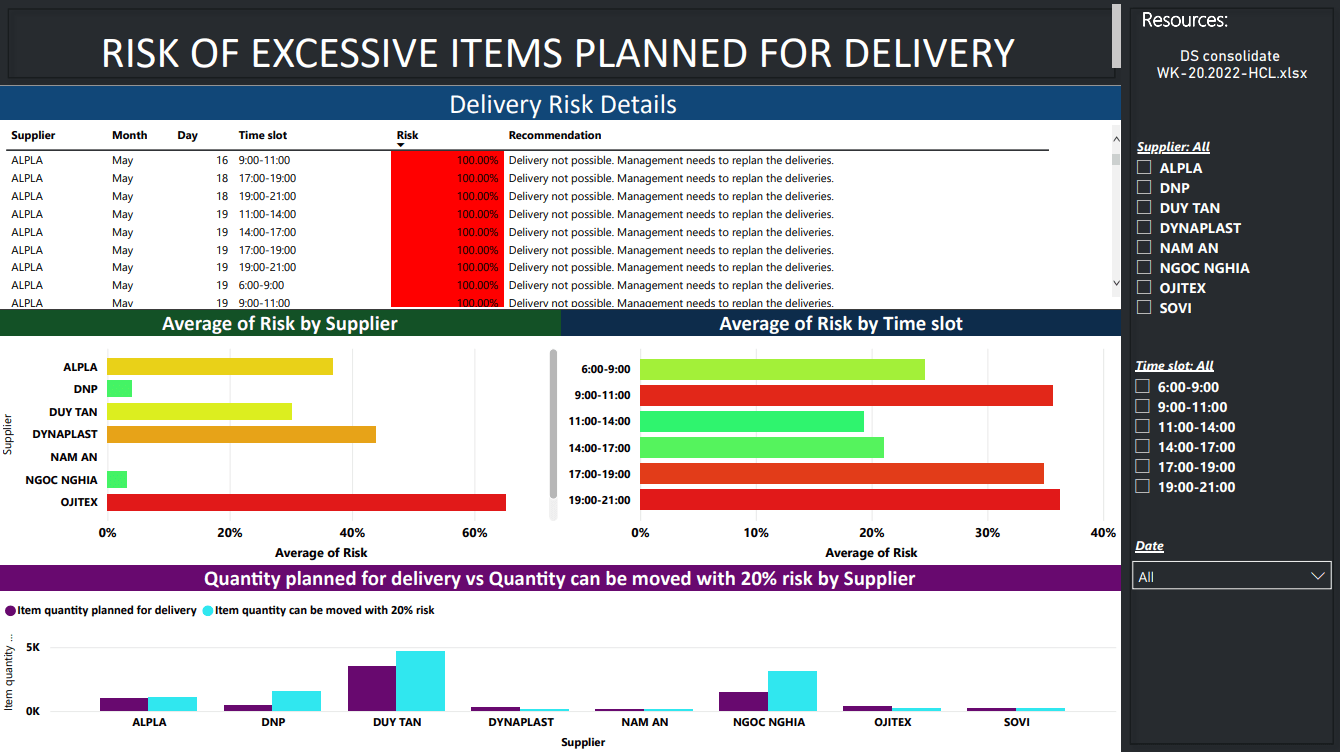

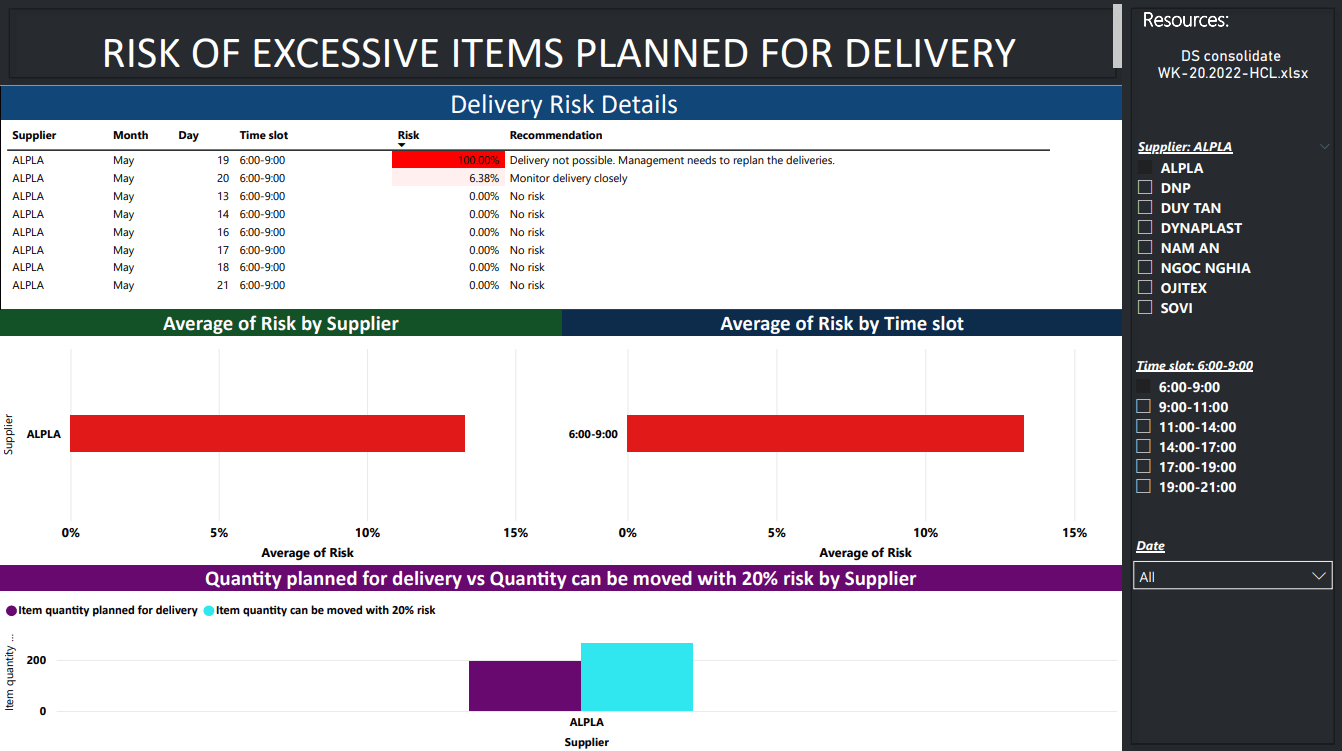

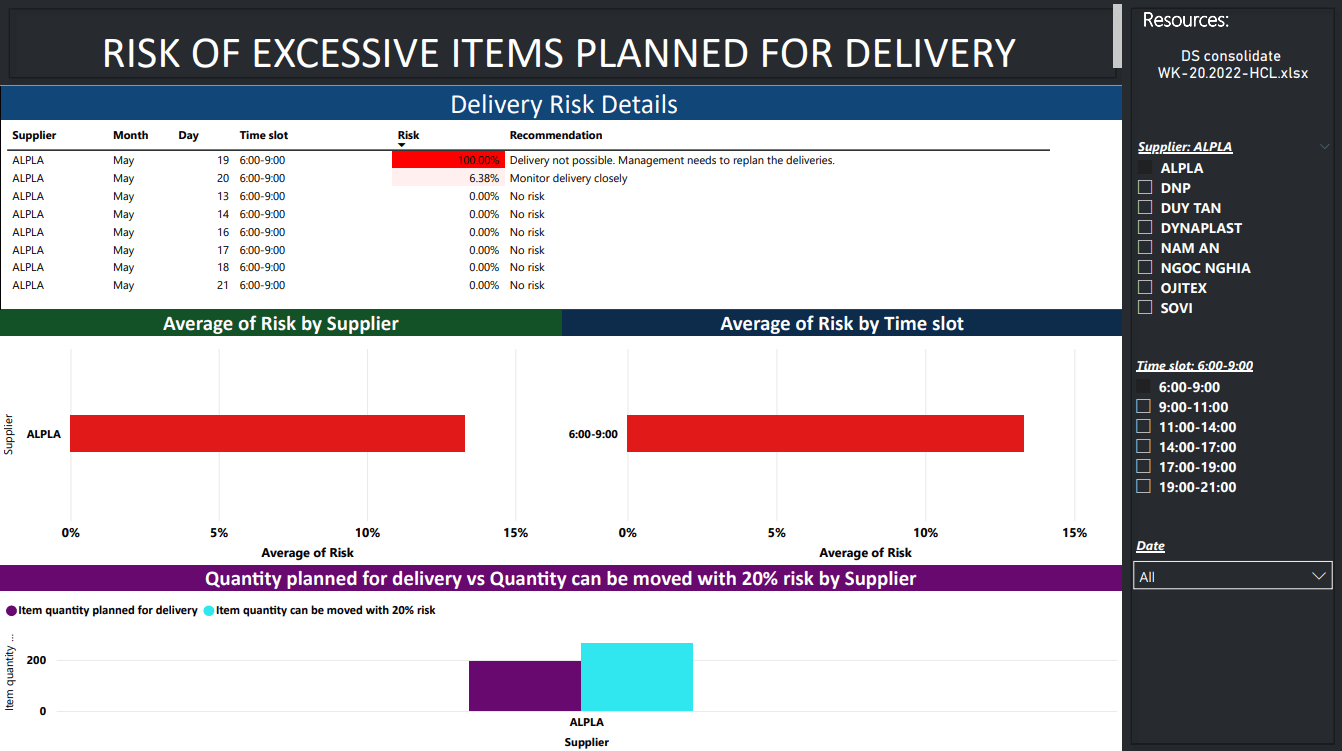

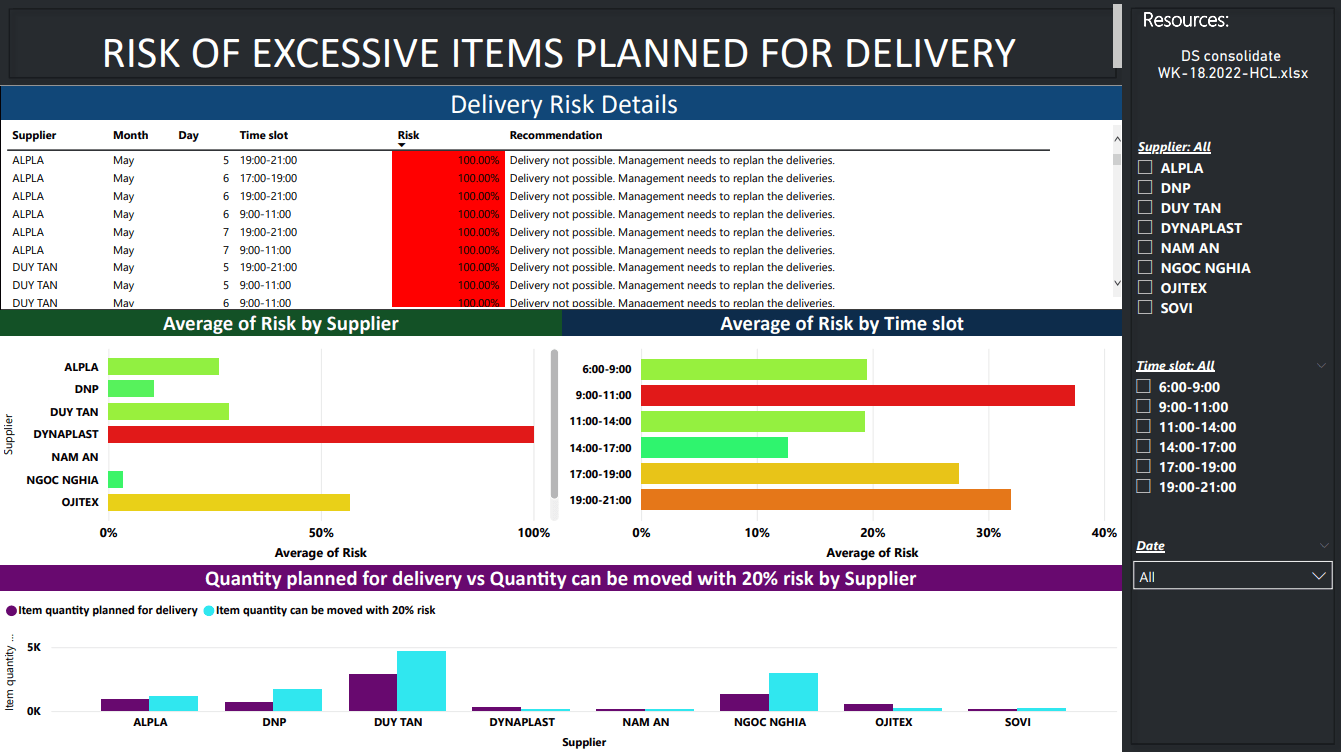

A PowerBI dashboard is used to build a visualization tool to highlight risks of excessive items planned for delivery and automatically recommends actions based on the associated risks.

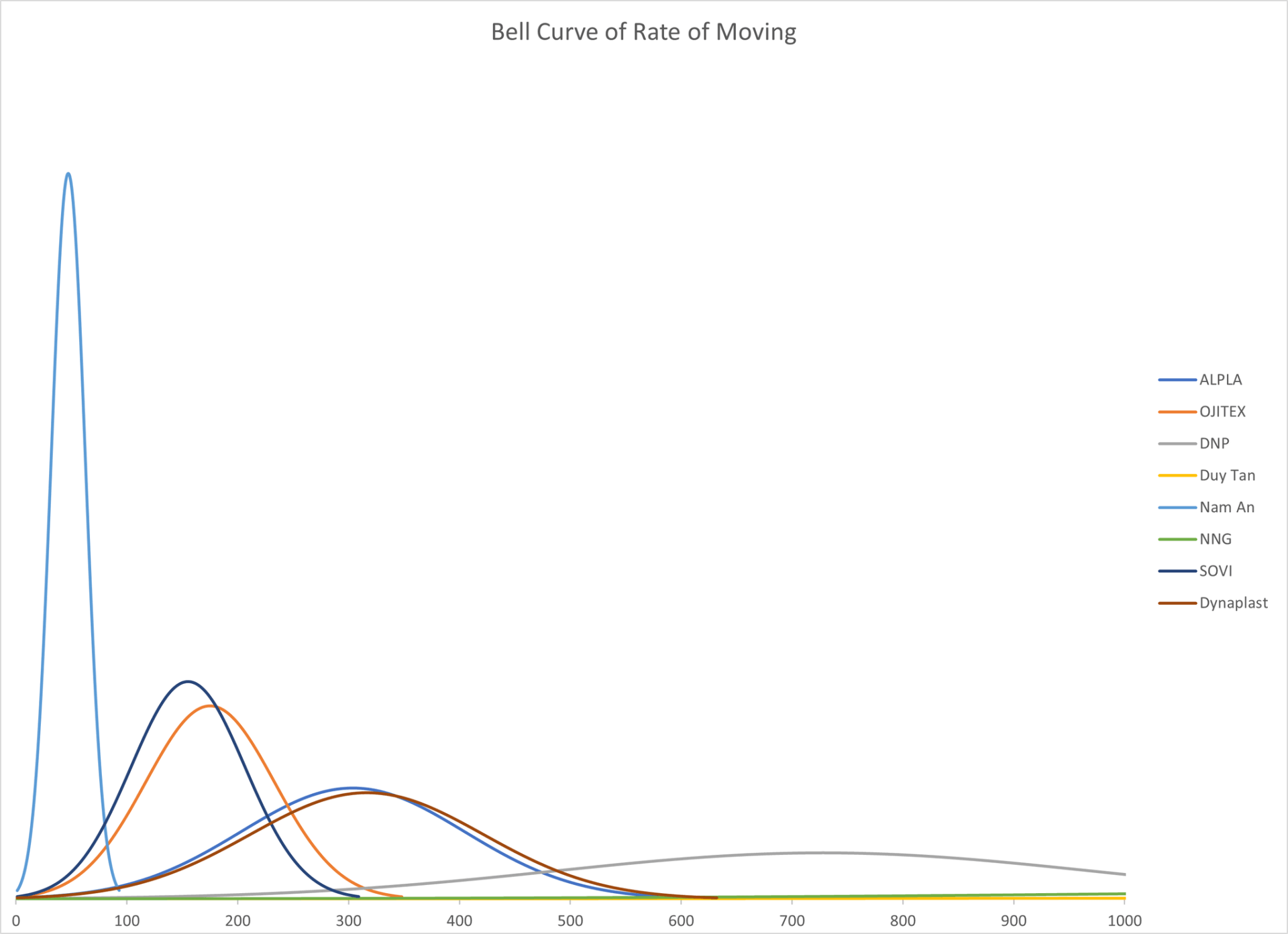

From past DS and Transactions (timesheet of trucks entering and leaving the factory, as named by Unilever) datasets, the team filter the data and analyze them to create a bell curve model of the Rate of Moving of items (items/minute) by all the suppliers. Utilizing this model, an algorithm was created to assess the risks of current and future DS. The dashboard also gives recommendations on each delivery based on the risk.

For future work, other risks should be implemented. Furthermore, at the moment, the dashboard is purpose-built and limited in its use cases. However, this sort of problem is also represented in other factories, so generalization of the dashboard to apply to other businesses should be considered.

Demo Video