Vision Loader package for Machine Tending with ABB robots

Hemalee Uttara Sankhini Ediriweera

Khai Vu

Thang Pham

Ovindu Hennadige

The development of technology in the world is influencing the function of industries while making major changes by the day. Vietnam is one of such country with a rapidly growing automation industry. With the increasing number of industries moving towards Vietnam, as well as its highly expected demands towards quality and quantity of manufactured products in the supply chain to reach the competitive market, the complexity of the robots used is required to increase to create more flexibility for each task to be completed.

The existing methods that are currently used in industries do not comply with the ability to work with a large variety of products. Hence, most companies suffer from setup time or capacity. The focus of this project is to develop a more flexible system that can swiftly adapt to more improved design changes as well as corporate multiple products and ranges simultaneously which leads to a more improved supply for the demand without the compromise of time, quality, or cost. Compared to the current existing tending application, The FlexLoader robotic solution introduced by ABB is used for machine tending which, comparatively can load and unload fragile workpieces with complete geometries into a machine tool.

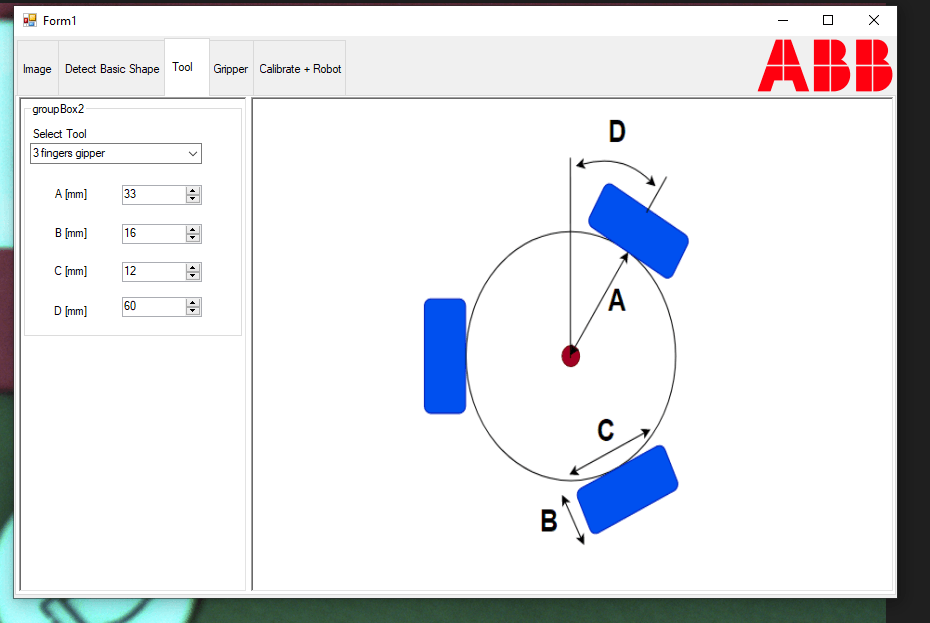

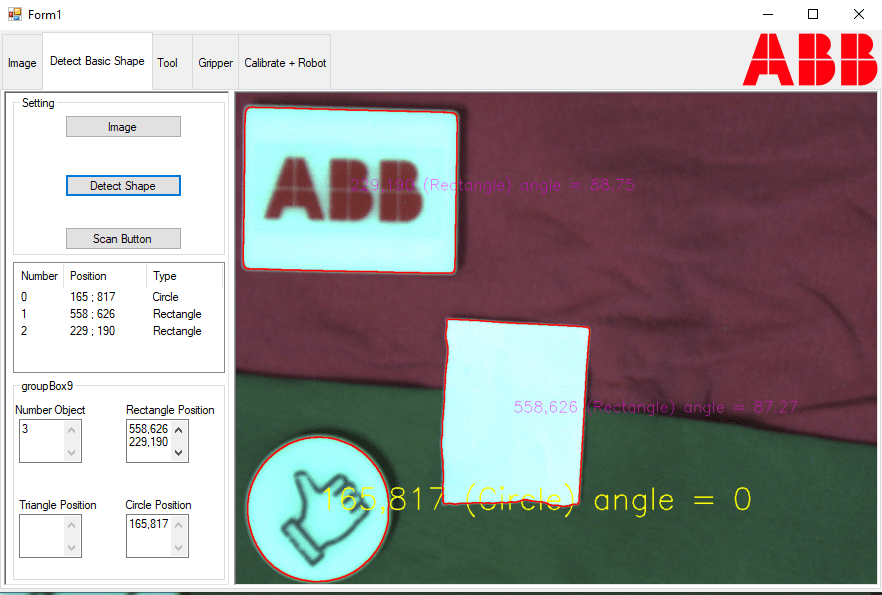

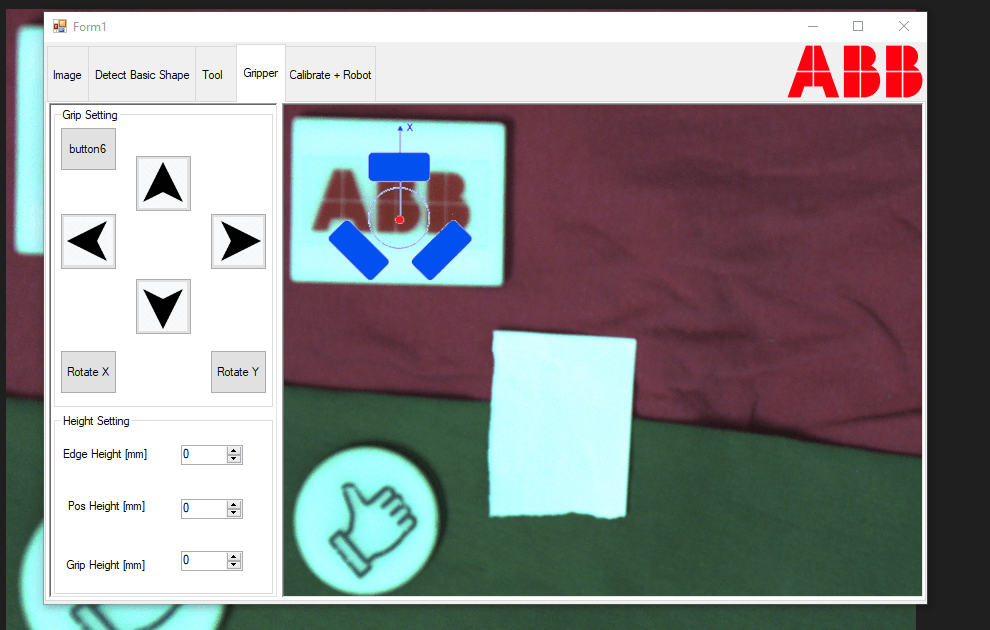

This project consists of two tasks in which we will be focusing on its software aspect in order to develop a vision loader package that allows us to identify the object, identify the shape of the object and choose the suitable robot arm and the specific angle to pick and place. As per the requirement of the project, the objects are square, circular, and triangle shapes. With the completion of the project, the company is able to modify the system as furthermore detailed requirements while using the project as a foundation in order to implement in real-life industries.

Demo Video