Mixed Case Palletizing System with ABB Robot

Dilsha Hattotuwa

Sachin Dissanayake

Felicia Salgado

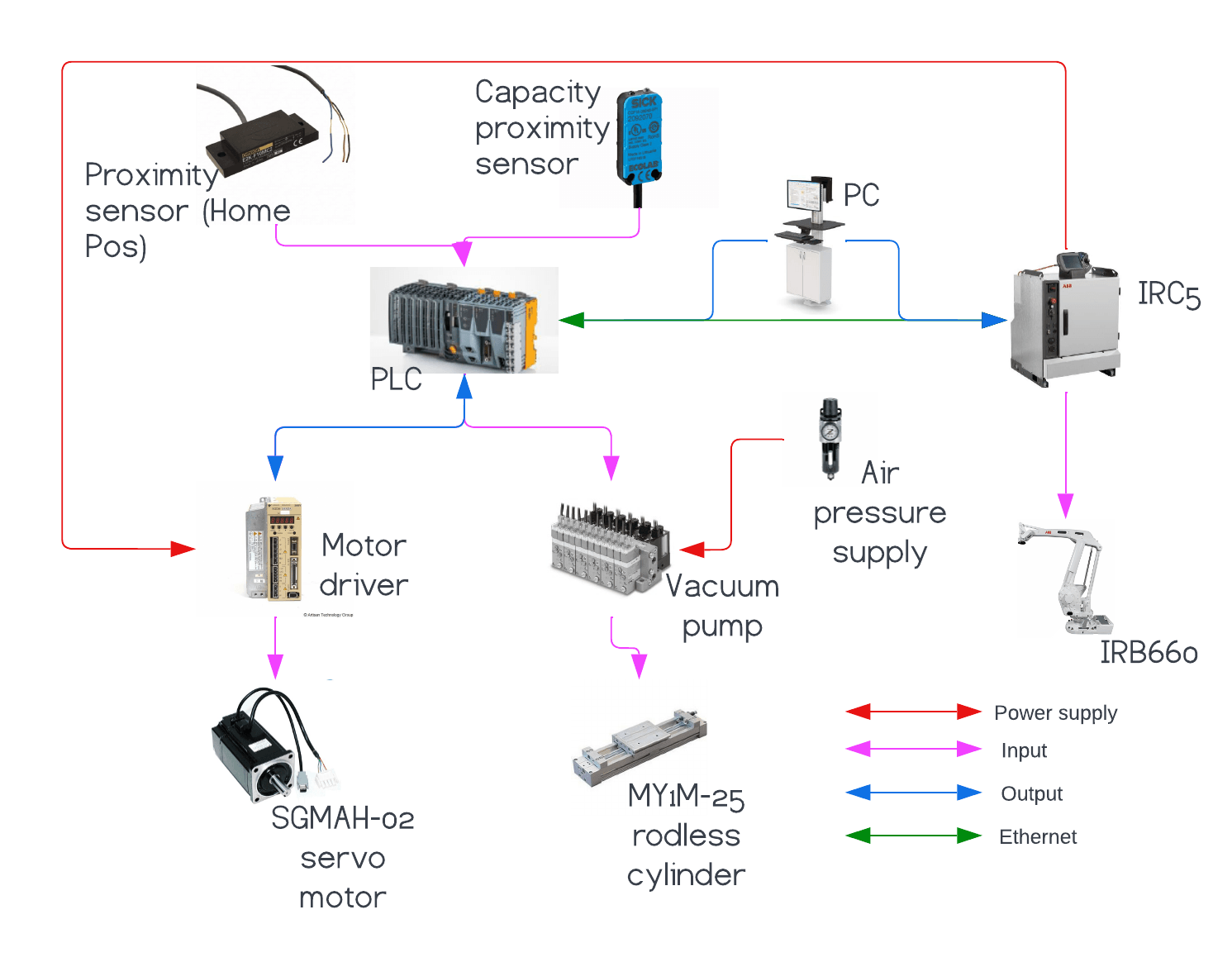

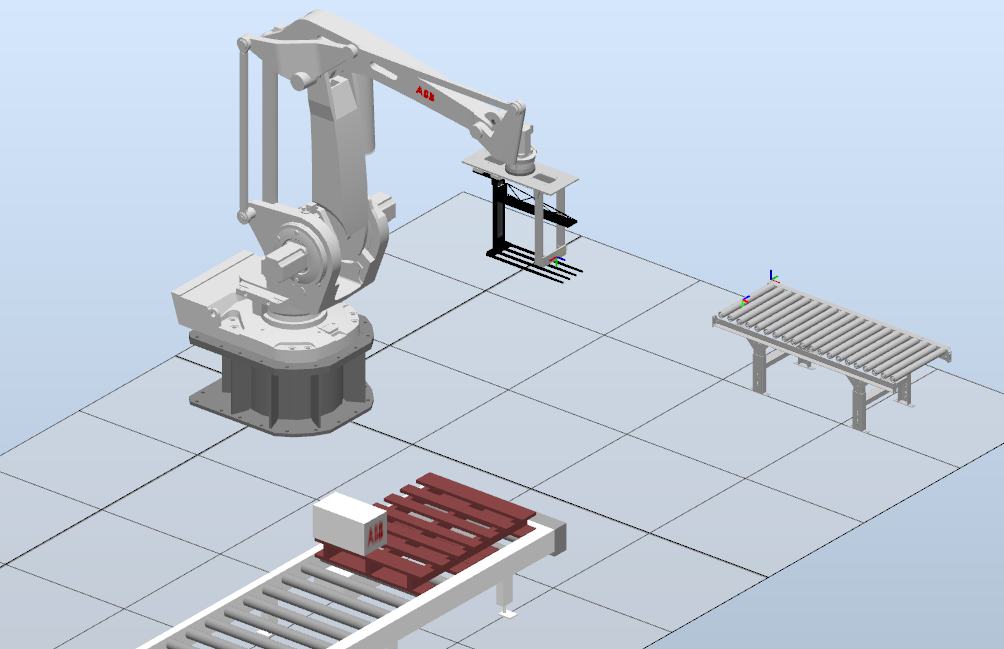

In this project we’ve designed an EOAT gripper for ABB’s palletizing robot IRB660. This gripper specifically caters towards mixed case palletizing where packages of various dimensions, shape, weight, and product type are stacked on a single pallet. ABB aims to fully automate the process of mixed case palletizing by designing an AI software to generate optimised stacking solutions for customer’s specific orders.

Our team’s contribution in this process is twofold. The major component being the design of a gripper for the IRB660 robot (180 kg payload) while also designing and manufacturing a cost effective gripper to test the stacking algorithm that’s being developed.

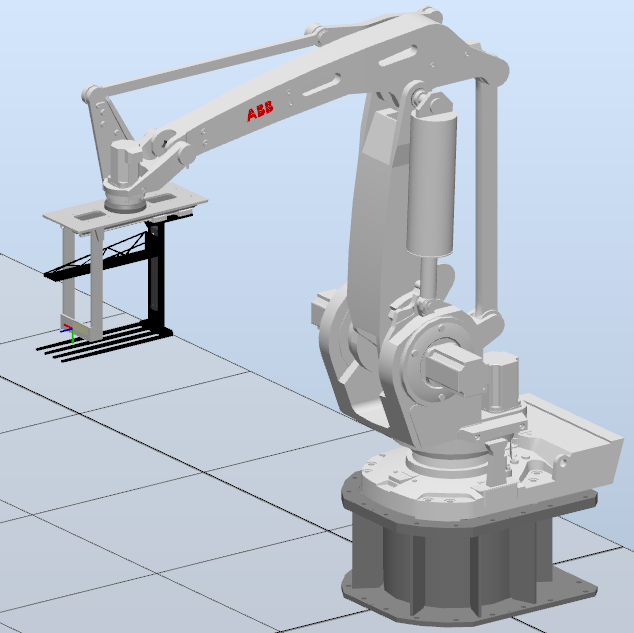

The IRB660 gripper is a single working zone fork gripper with a clamping mechanism to ensure product safety in high speed movements. A stationary plate mounted at the front aids in product placement by securely sliding the package into place when the forks and clamp retracts. The horizontal linear movement of the fork is controlled by a servo motor. Vertical movement of the clamp is pneumatically controlled via a rodless air cylinder. This lightweight gripper (33 kg) is capable of handling 600 cases per hour with a 6 second cycle time. It has the ability to pick packages weighing up to 15kg. The sleek design of the gripper is ideal for collaborative robots in palletizing which can further improve the throughput of the palletizing process.

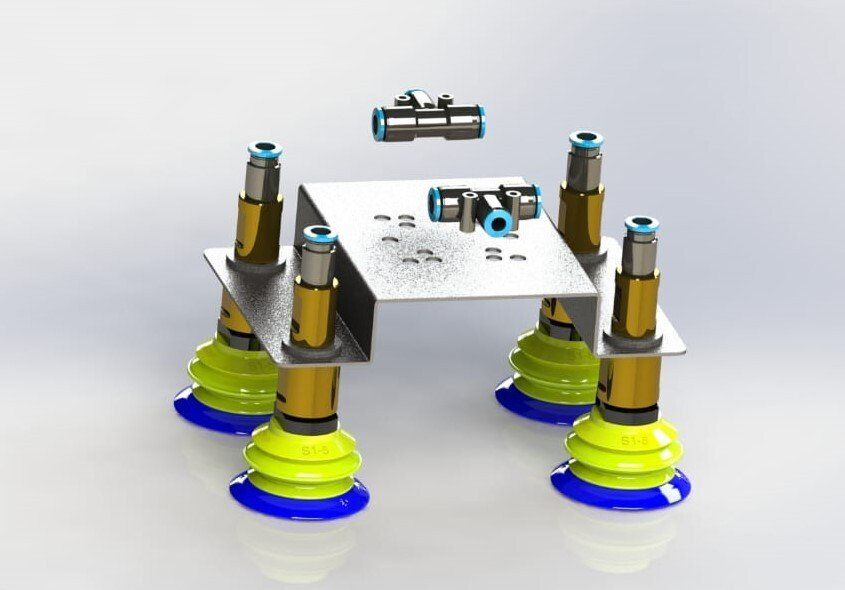

For the purpose of software testing our team developed a small scale vacuum gripper which is more cost effective than developing a gripper with numerous mechanical movements and electromechanical components. The simplicity of the gripper is an added advantage in programming the robot as readily available RobotStudio resources (work-cell and Rapid code) can be utilised. The gripper consists of 4 vacuum suction cups each with a vertical lifting force of 56.6N at 40kPa. A key feature is the custom designed flange that is adaptable to 3 ABB robots (IRB1410, IRB1520, IRB2600) so that any available robot can be used for software testing.

Demo Video