A DIGITAL TWIN FRAMEWORK FOR PRECISION LIGHTING IN INDOOR FARMS USING ROBOTIC AND IOT SYSTEMS

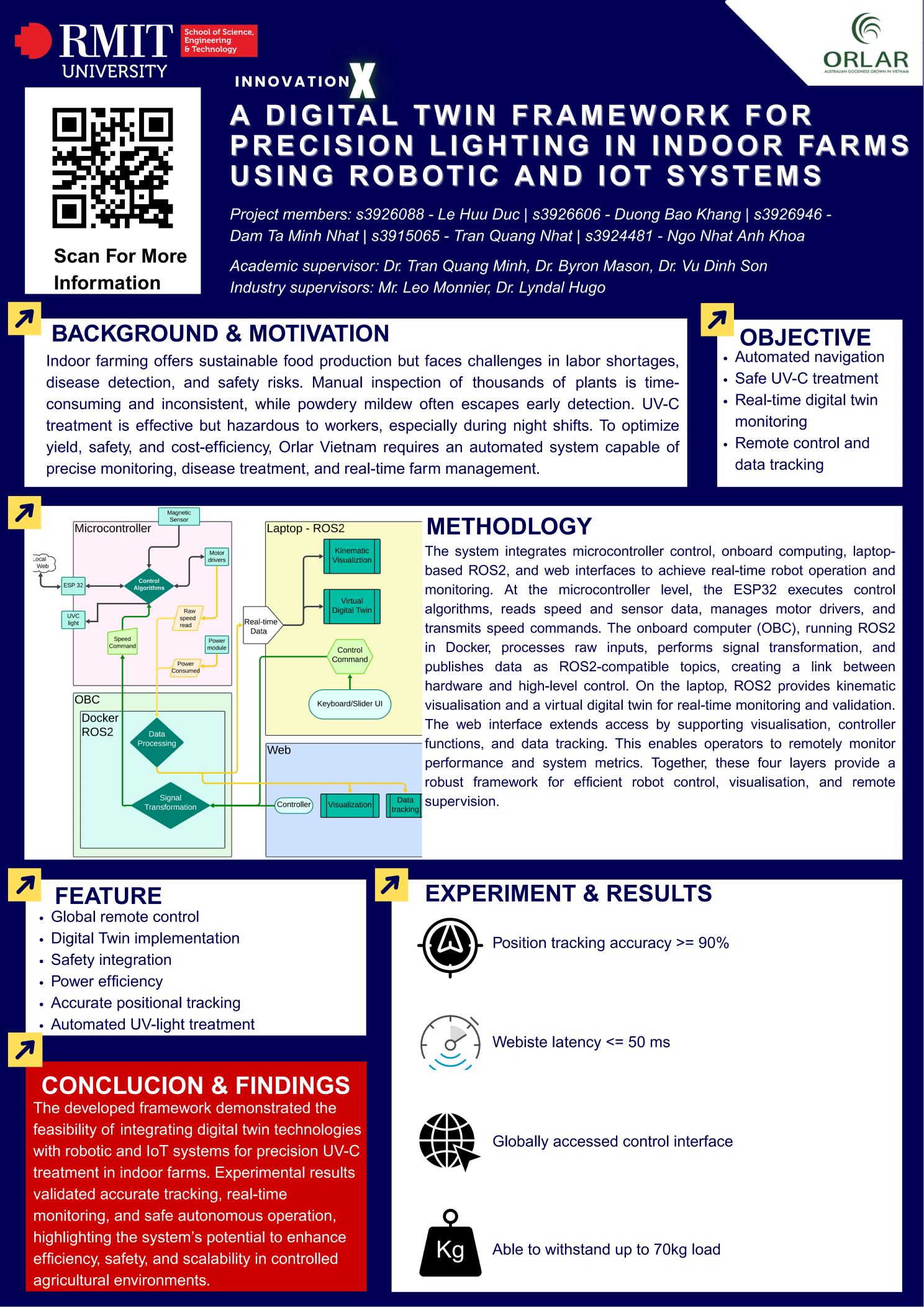

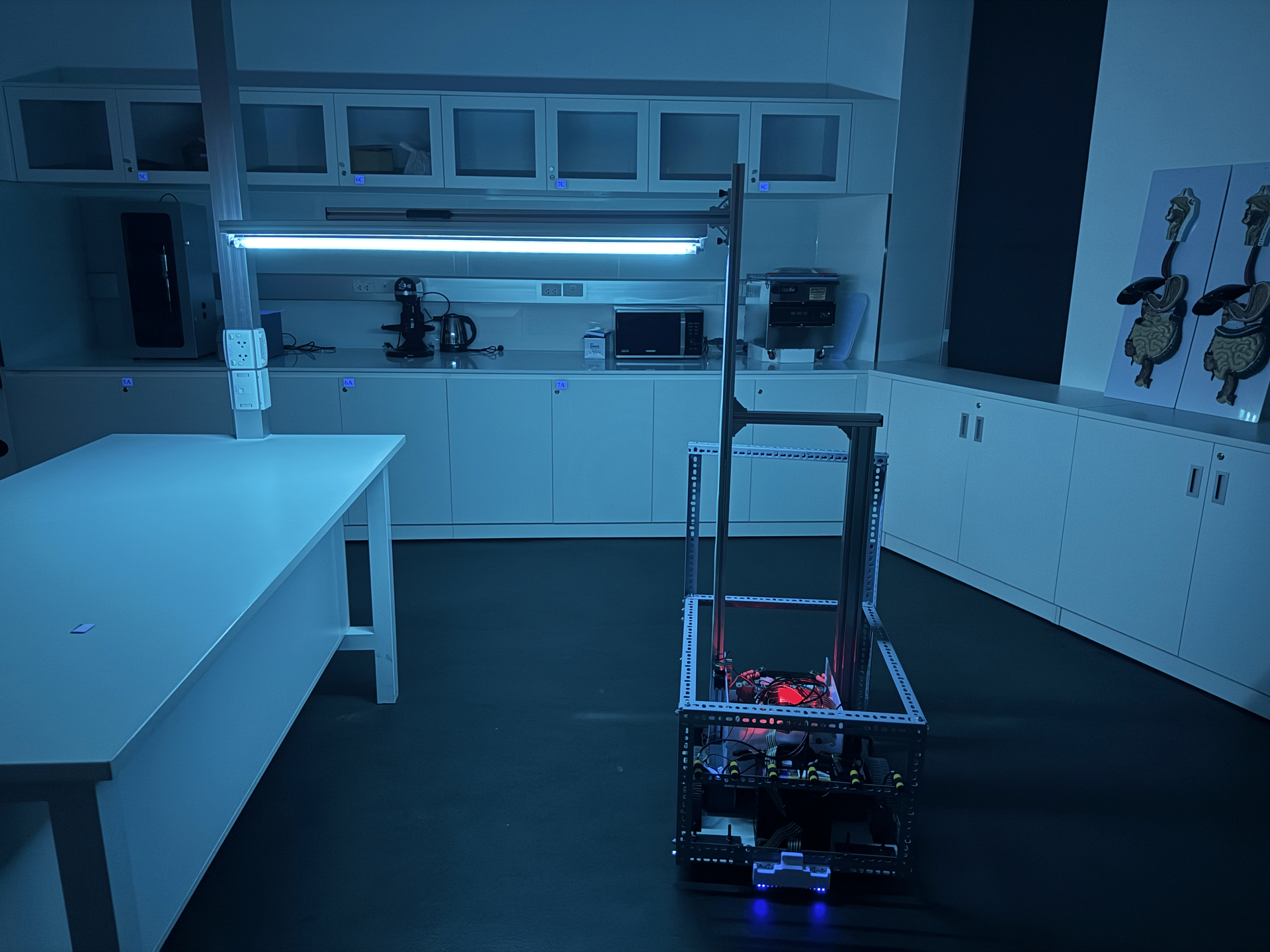

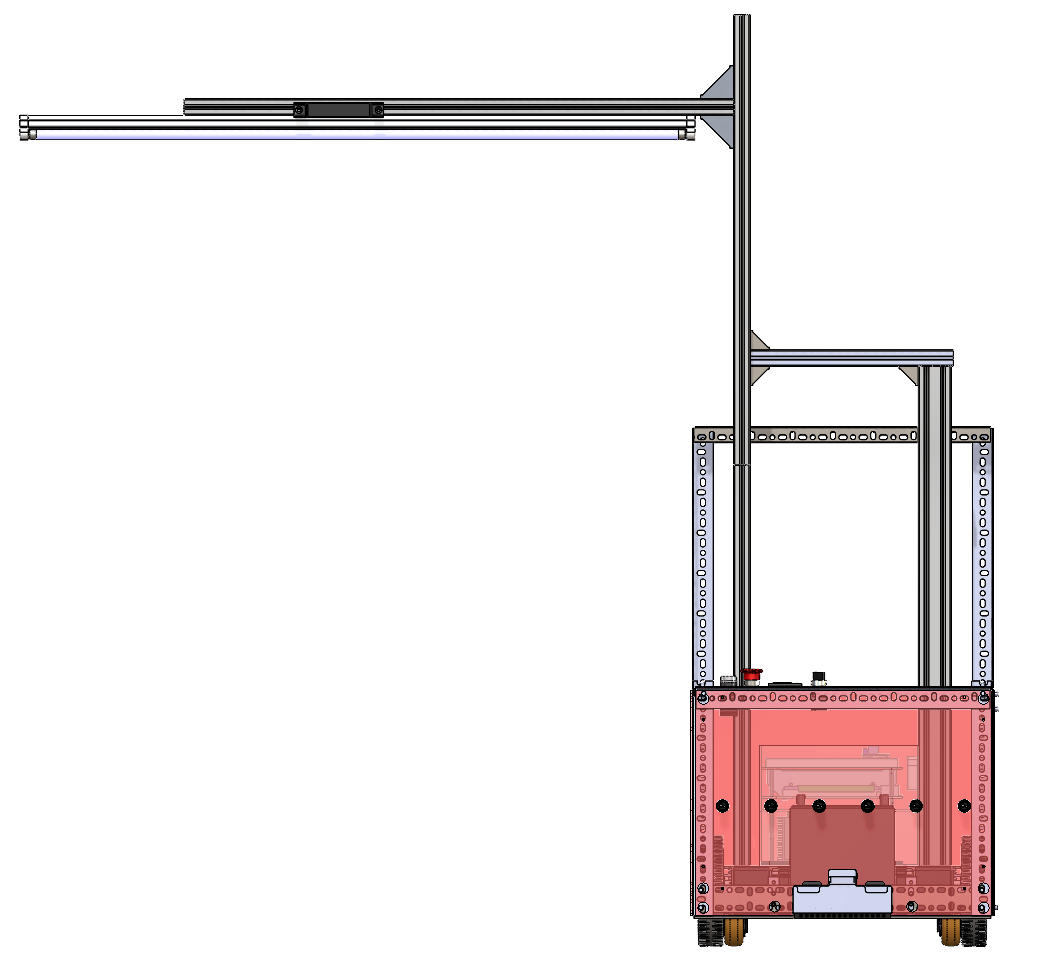

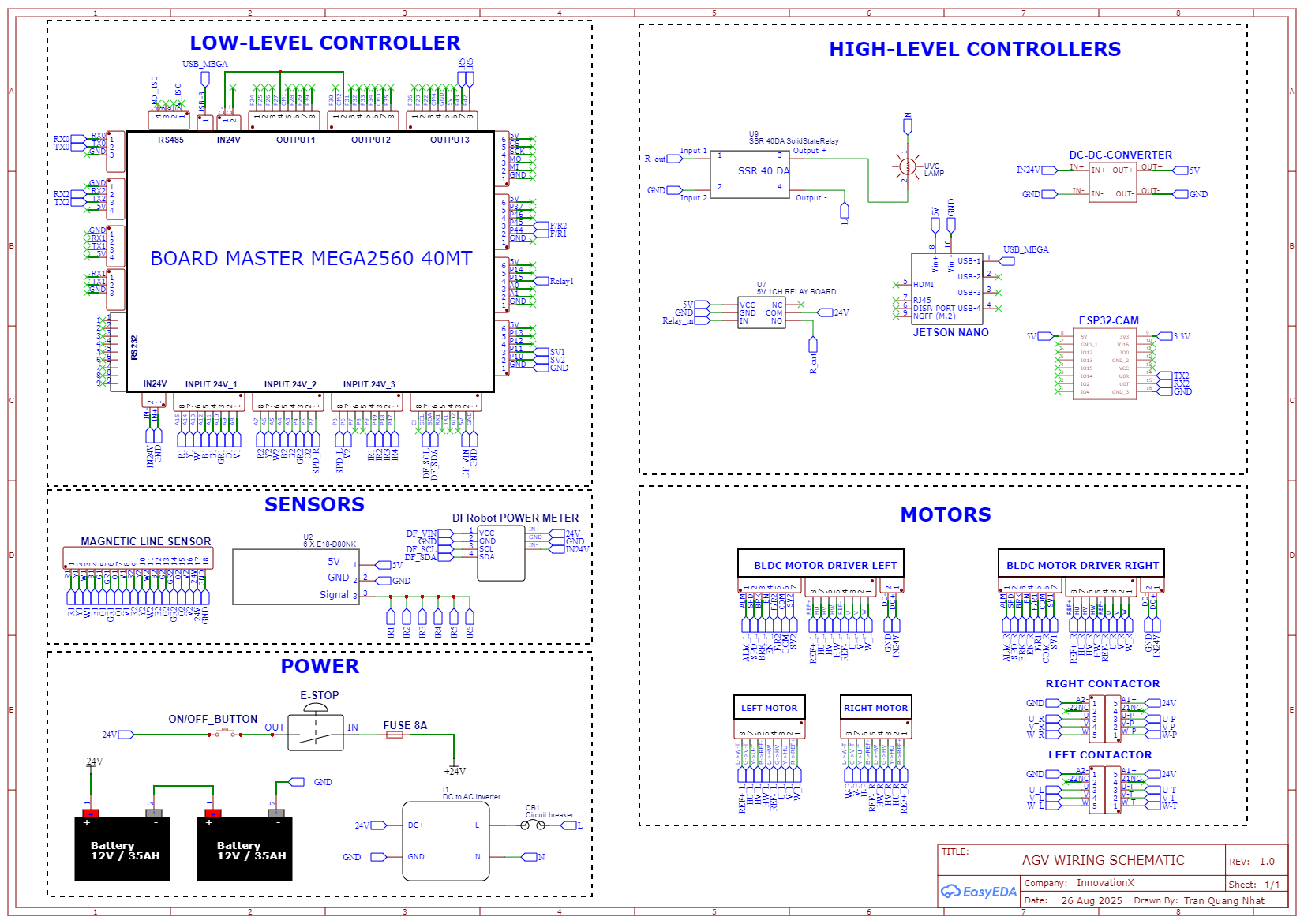

This project presents a four-layer digital twin framework integrating robotic and IoT systems for precision UV-C treatment in indoor farms. Motivated by labor shortages, inconsistent manual inspection, and health risks associated with pathogen control in agriculture, the system aims to automate plant monitoring, disease management, and real-time farm supervision. The architecture comprises a microcontroller level (ESP32) for low-level motor and sensor control, an onboard computer running ROS2 in Docker for signal processing and data publishing, a laptop-hosted ROS2 environment for digital twin visualization and high-level coordination, and a web interface for remote monitoring and control.

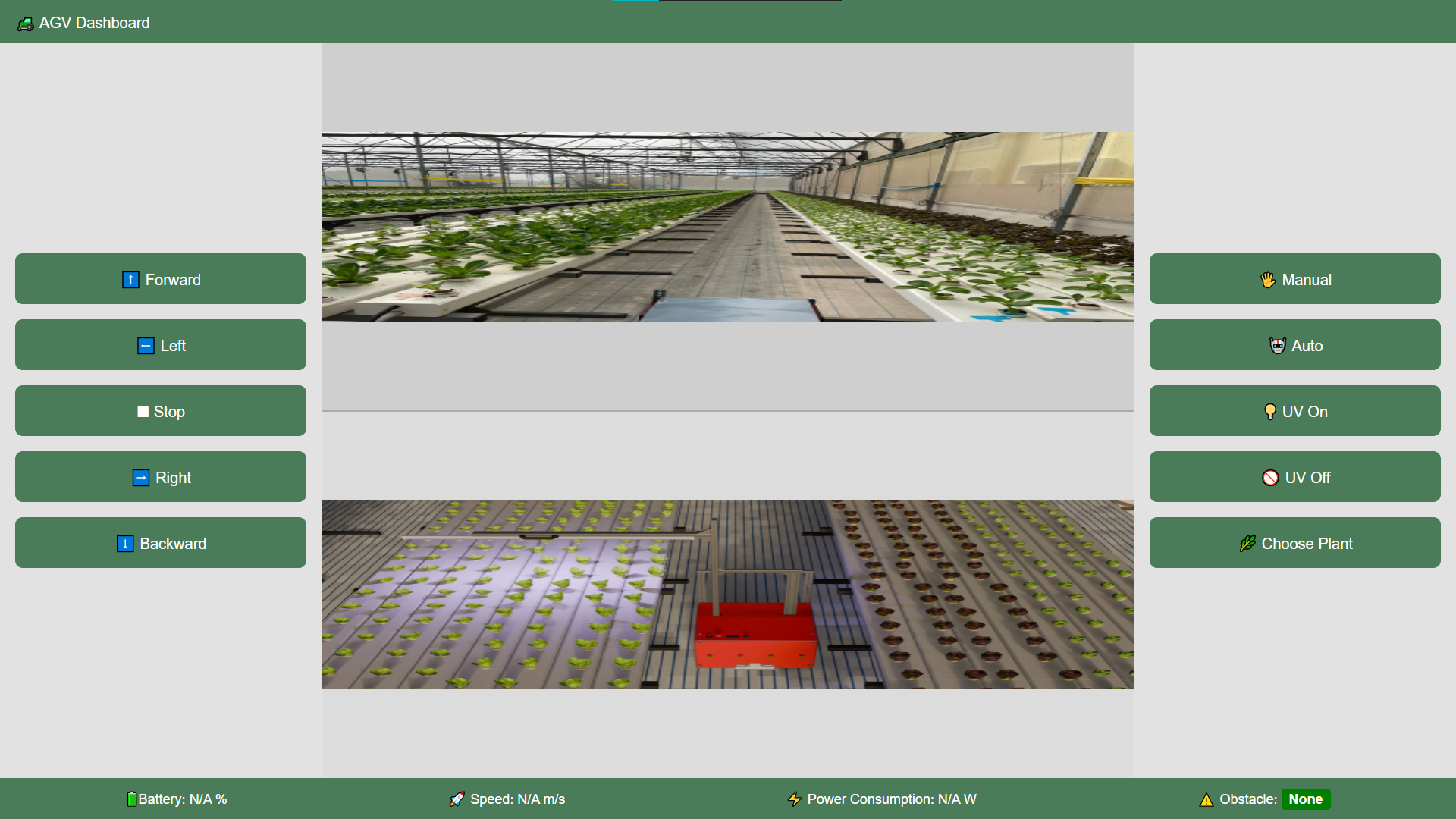

The digital twin synchronizes physical and virtual environments, enabling operators to track robot kinematics, issue commands, and view sensor feedback from any location. Key features include accurate positional tracking, automated UV-light disinfection, safety interlocks, and energy-efficient operation. The interface maintains low latency (≤50 ms), supports global access, and enables robust performance monitoring.

Experimental results validated system reliability with ≥ 90% tracking accuracy, effective load handling up to 70 kg, and consistent real-time feedback. Overall, the framework demonstrates strong potential to enhance operational efficiency, safety, and scalability in controlled agriculture, supporting precision farming and sustainable food production initiatives.