Lean Digitization System Hi Performances Deployment

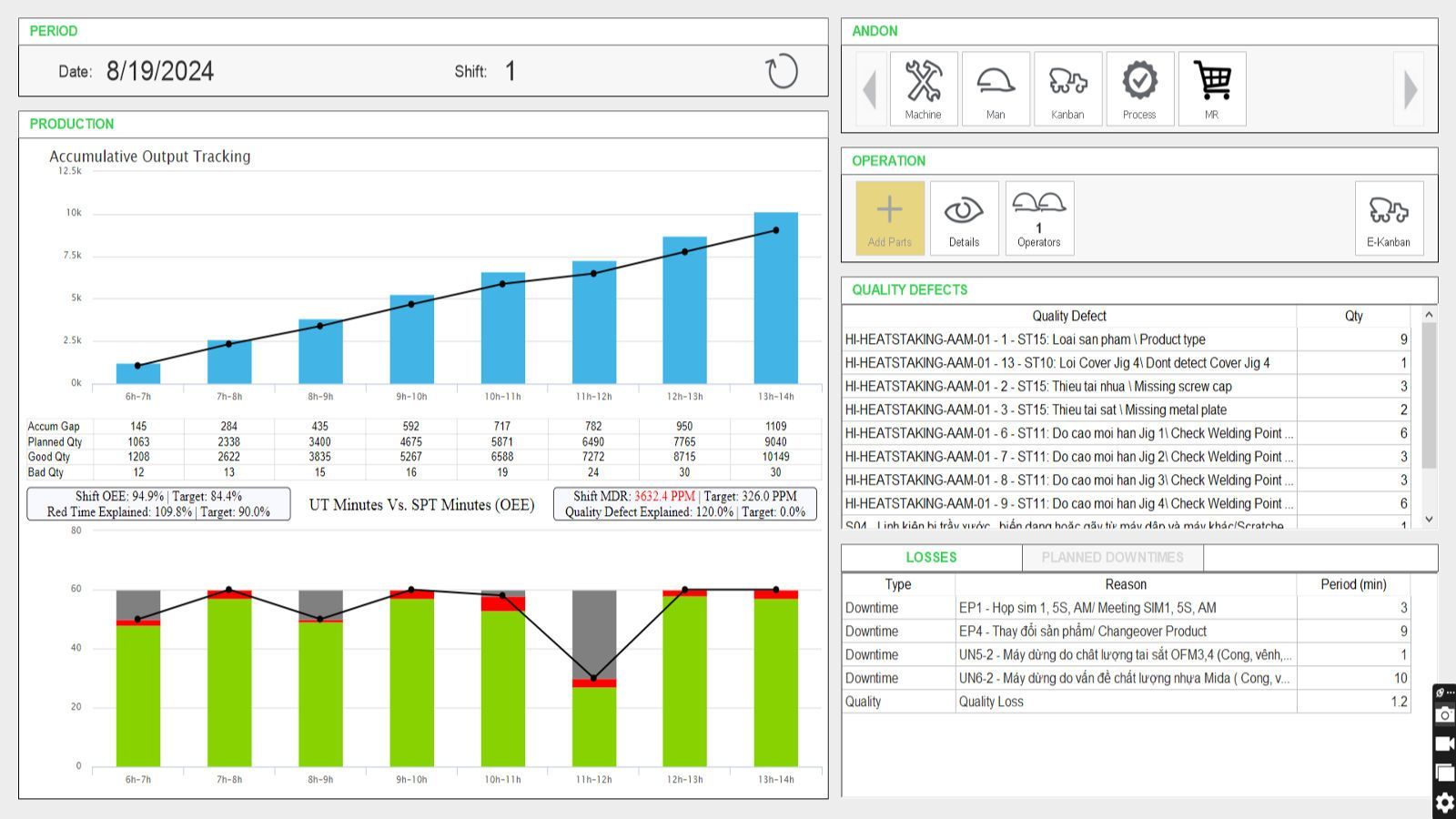

The Lean Digitization System (LDS) Hi-Performance Deployment project at Schneider Electric Manufacturing Vietnam demonstrates significant progress towards the integration of Industry 4.0. This project's objective is to transform the collecting process of manual data via machine automation, improving accuracy and efficiency. An advanced, real-time data collection method will replace the existing manual data entry system for manufacturing parameters.

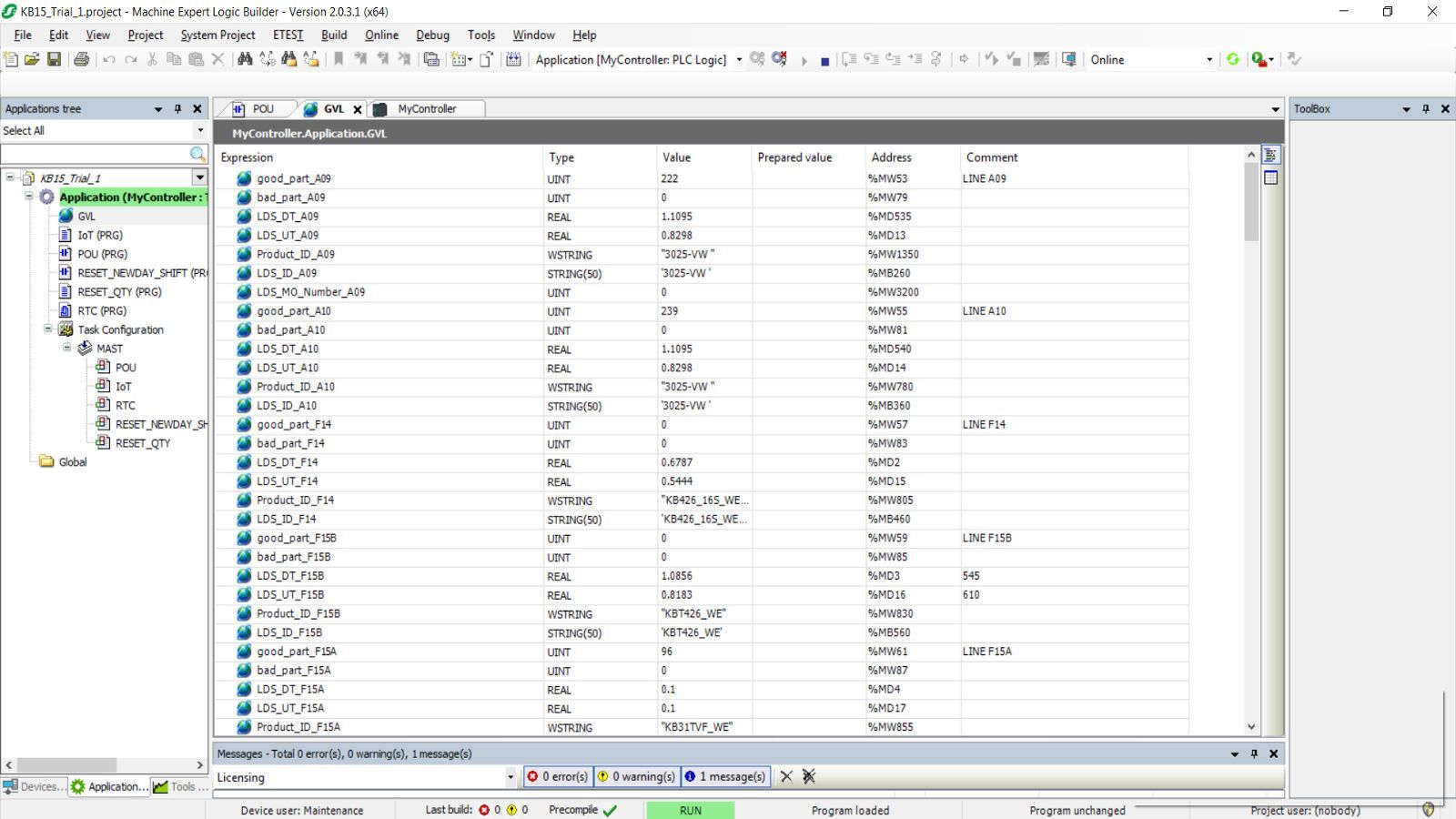

The LDS Hi-Performance component facilitates the establishment of direct links between automation machines or cloud servers, specifically Interlocking/MES systems, and the LDS database. The seamless interface would facilitate immediate capture of vital manufacturing data, such as good parts, bad parts, defect codes, and downtime reason. The success of the project depends on two main goals: attaining a 60% connection rate between current automation and semi-automatic equipment and the LDS database by 2024 and guaranteeing 99% accuracy in recording data transferred from machines to the LDS.

The technological scope includes programming for Programmable Logic Controllers (PLCs), PC programming (Visual Studio), establishing database connections using SQL database, and interacting with hardware using Ethernet TCP/IP, Schneider Electric software. Furthermore, the mechanics of drilling, operating with tools like screws, drilling machines, measures, etc. is also required. The implementation of this complete strategy will greatly improve Schneider Electric's capacity to actively monitor, evaluate, and optimize its production processes in real-time.