Robot integrated Manufacturing system model: An Industry 4.0 approach

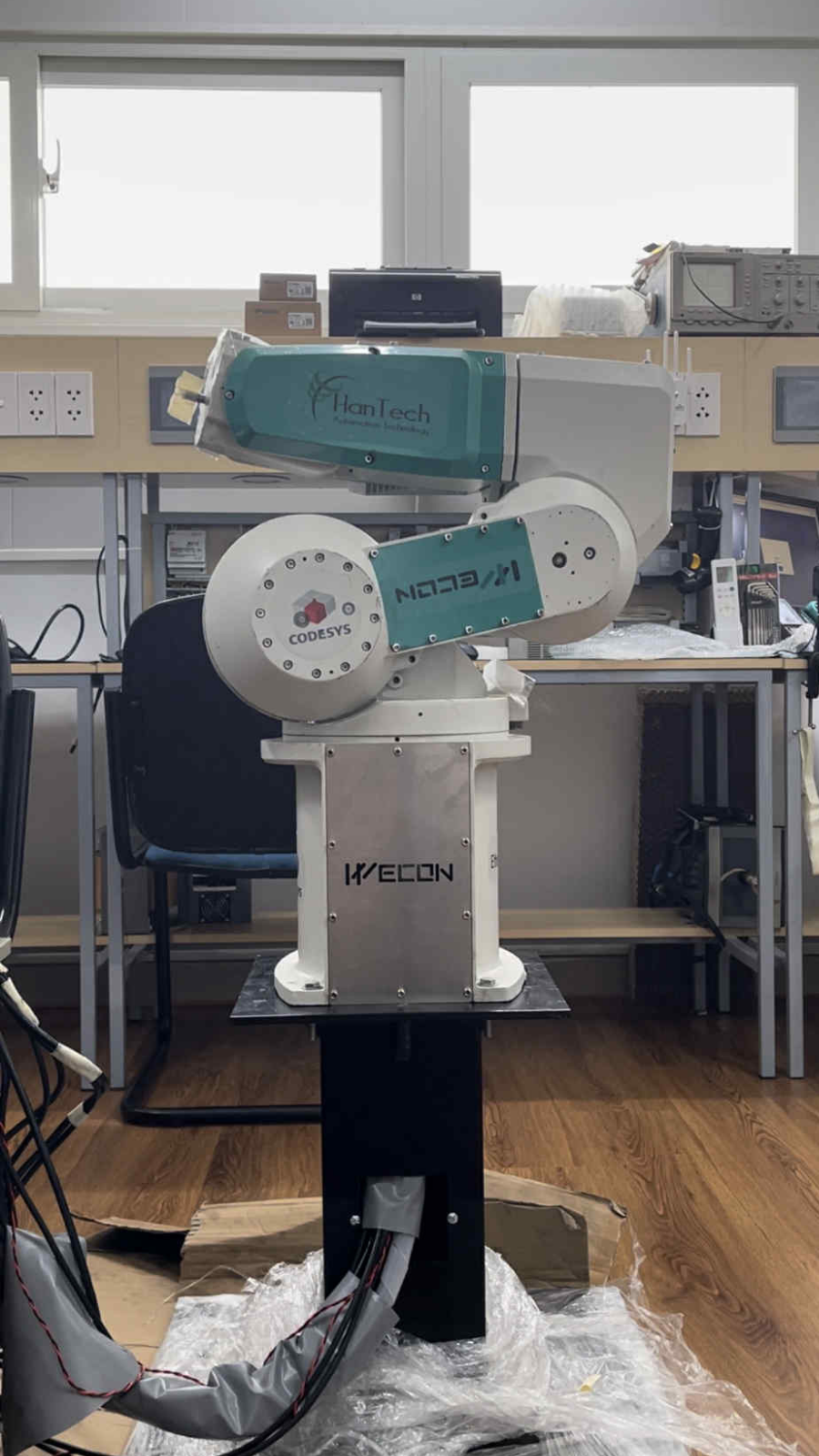

This project focuses on developing a Robot Integrated Manufacturing System Model based on Industry 4.0 principles, combining advanced automation, robotics, IoT, and real-time data processing. The system integrates a 6 DOF robotic arm with a PLC-based control system to perform precise pick-and-place operations within a simulated manufacturing environment. Key objectives include enhancing robot accuracy, implementing high-speed movements, and enabling seamless integration with a conveyor system.

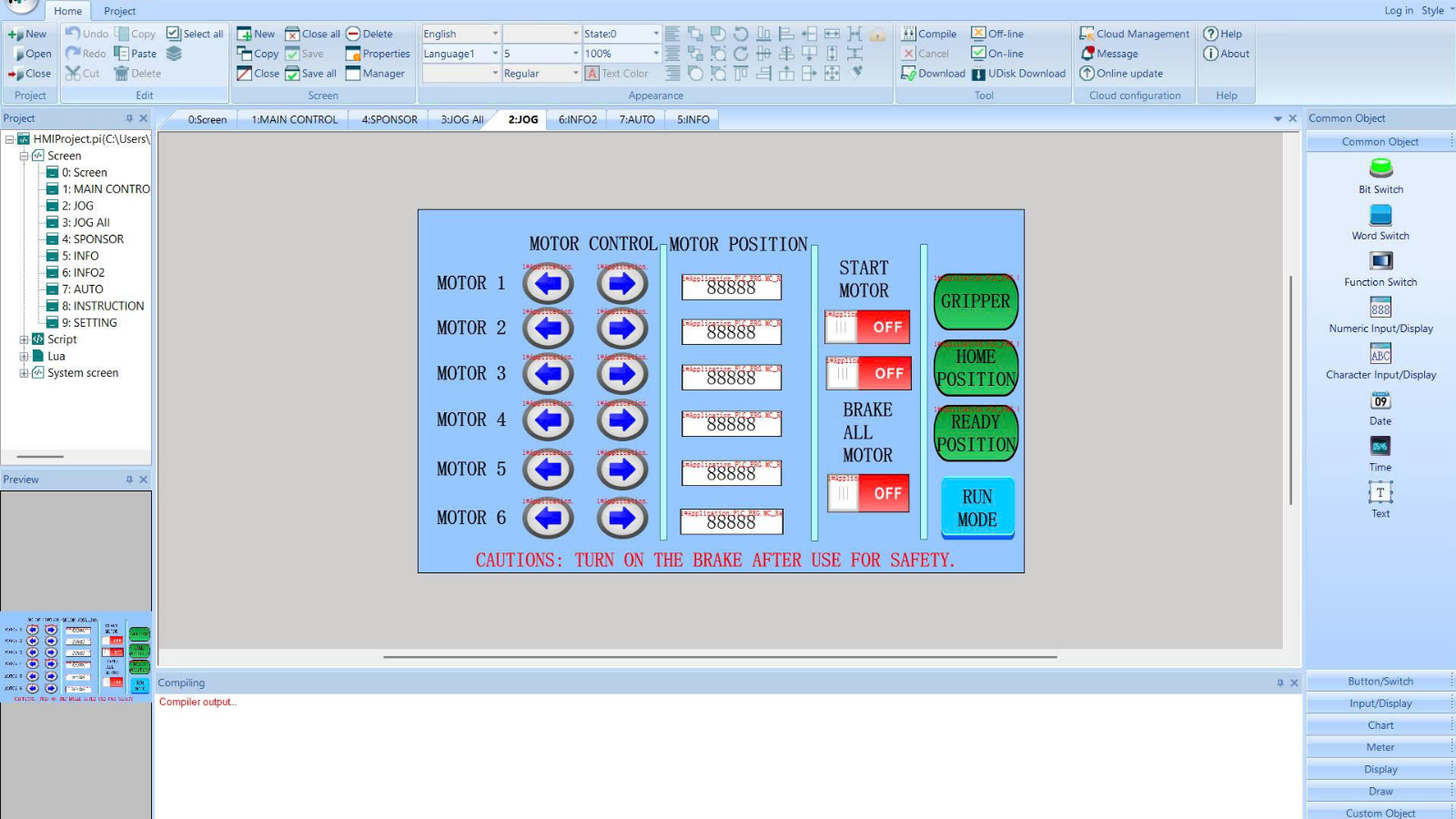

The project also develops a Human-Machine Interface (HMI) for intuitive monitoring and control while incorporating IoT capabilities for remote supervision and real-time decision-making through cloud-based platforms. The system will utilize the EtherCAT protocol to ensure high-speed, synchronized communication between sensors, actuators, and controllers.

Additionally, the project involves mechanical design, hardware assembly, and integration of a robotic gripper to handle objects of varying shapes and sizes. Performance will be validated through simulations and testing to ensure minimal positioning errors and high operational efficiency.

The outcome aims to deliver a scalable, modular, and future-ready automation solution capable of supporting upgrades such as AI-based vision systems and predictive maintenance, contributing to smarter manufacturing practices aligned with Industry 4.0 advancements.