Smart mixed case palletizing application with AI

In today's rapidly growing e-commerce landscape, efficient logistics operations are crucial for product delivery. Palletization—the process of arranging products on a pallet for warehouse storage and transportation—remains one of the most effective methods for moving both similar and mixed products. This approach helps companies improve inventory management and cut costs by shipping consolidated items to nearby destinations.

Working with ABB, we developed a Smart Mixed-case Palletization project to create an efficient system for palletizing products of different sizes and weights.

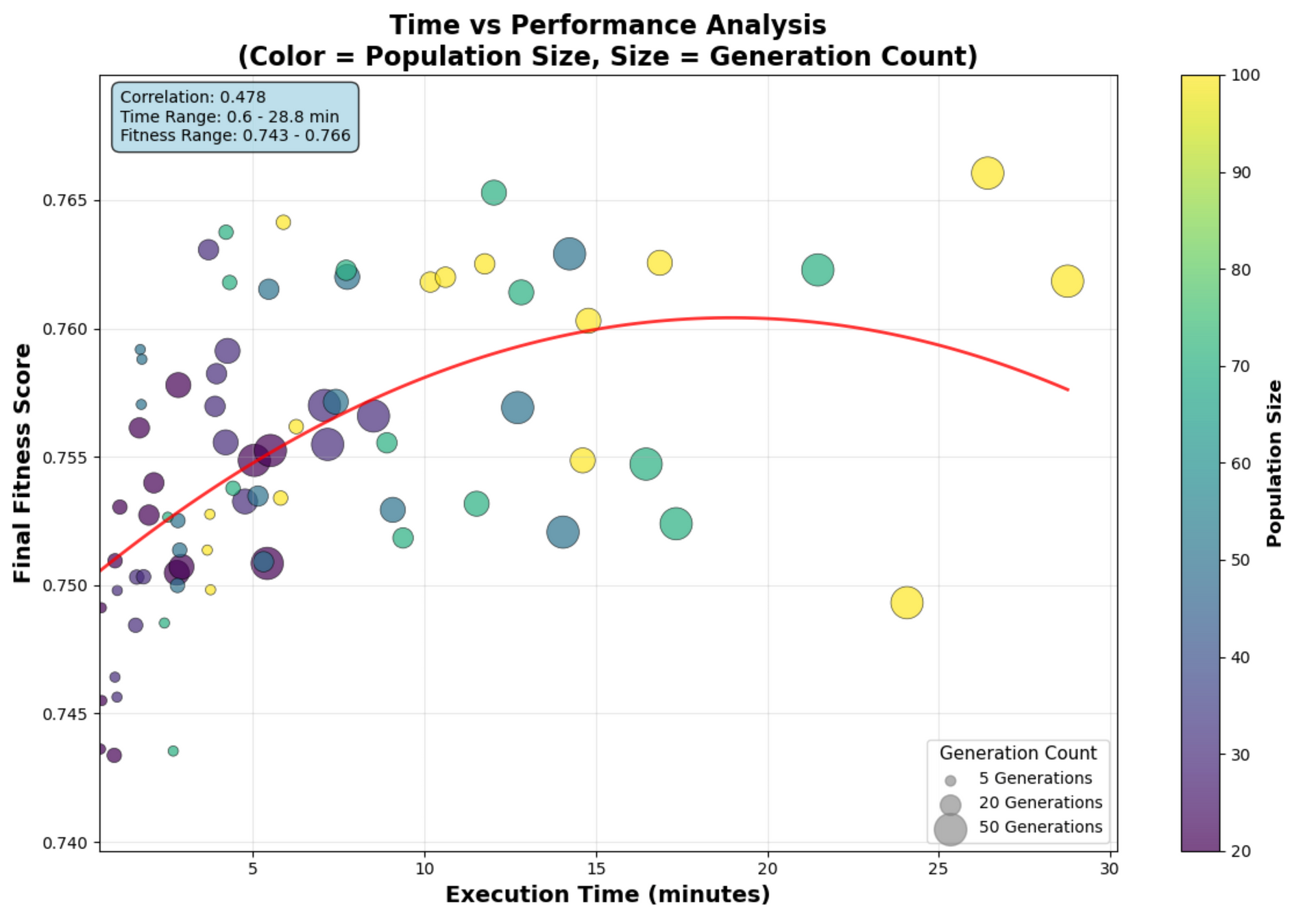

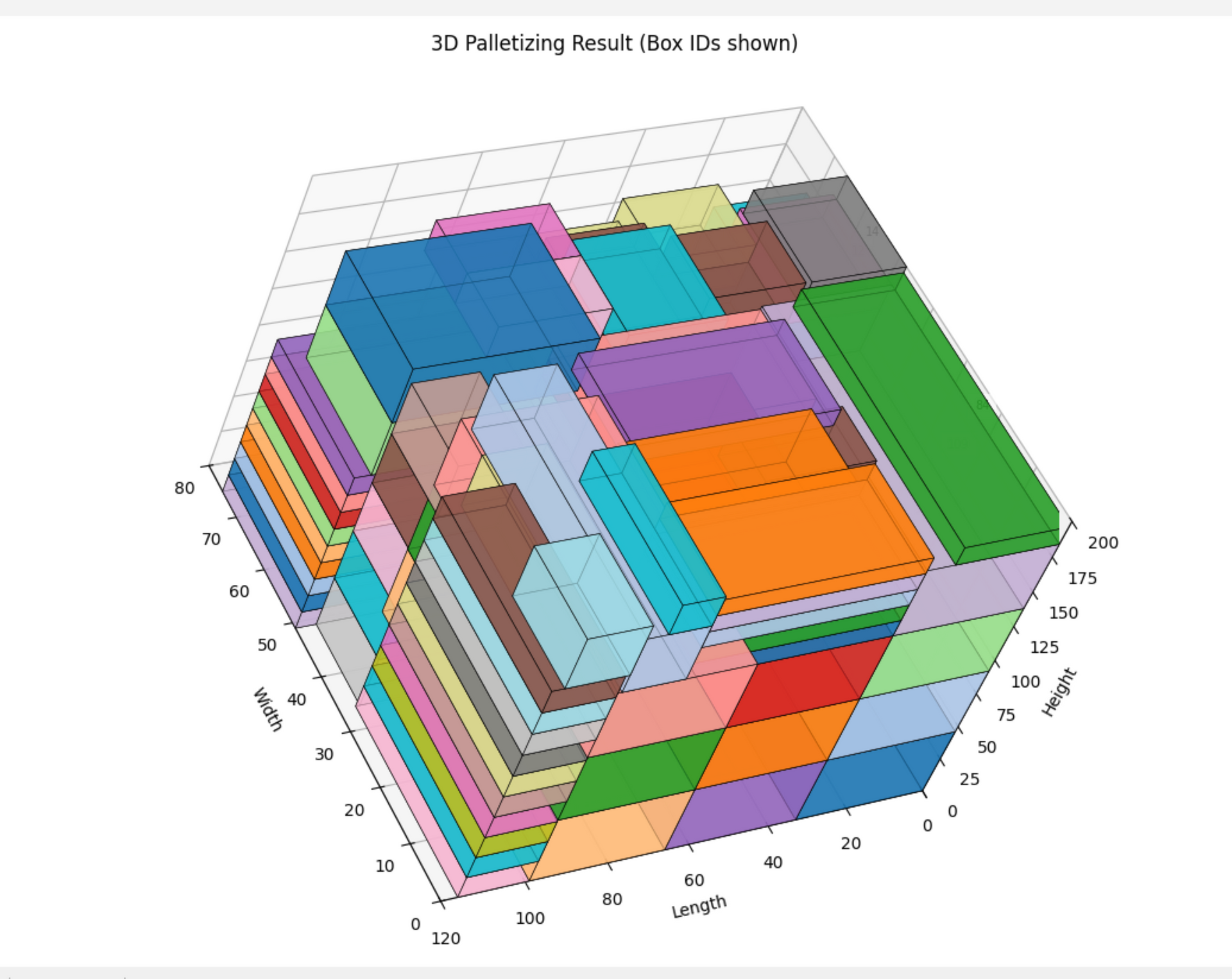

Our solution combines an efficient palletizing algorithm with an intuitive graphical user interface (GUI) that visualizes the entire process.

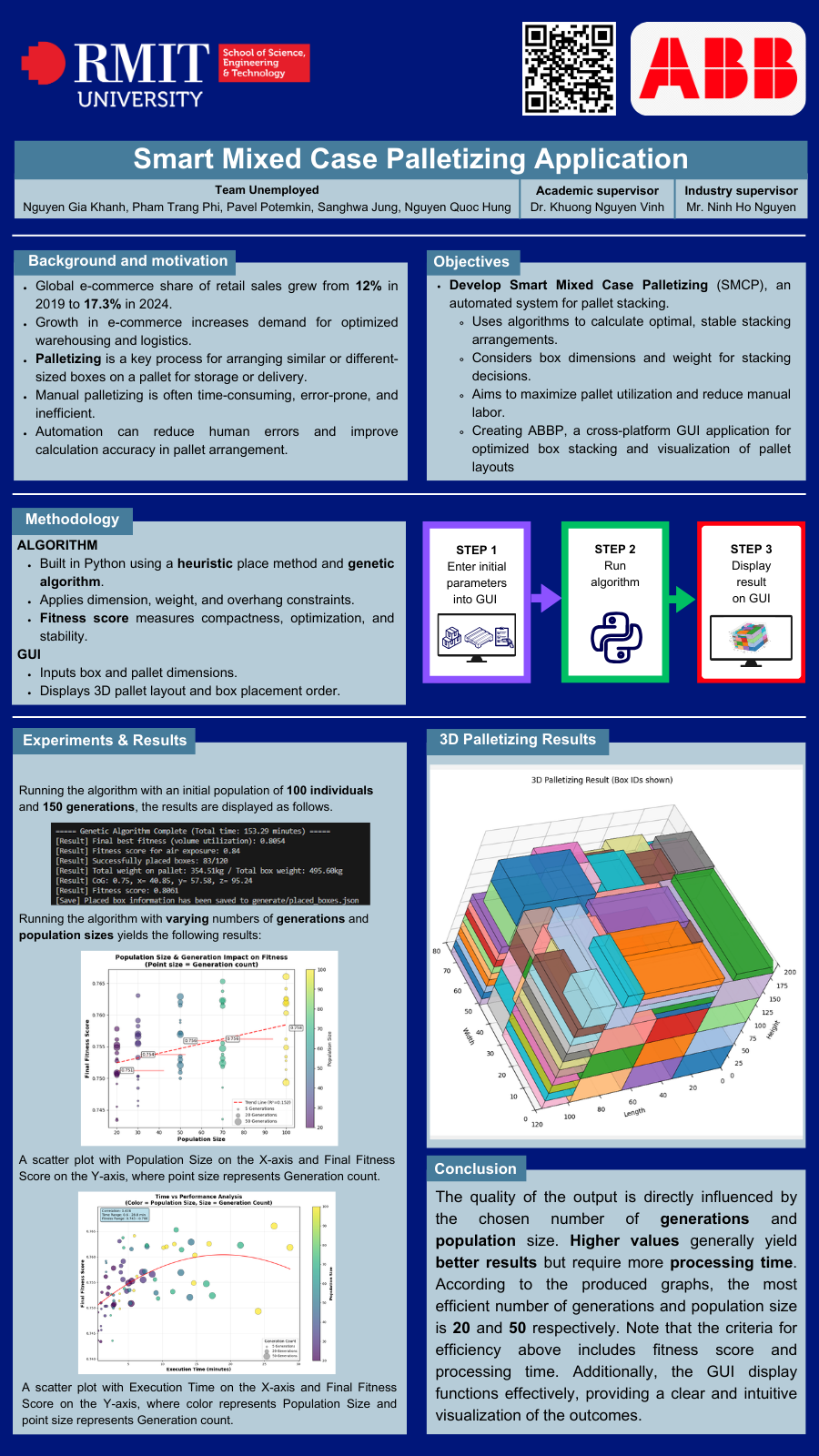

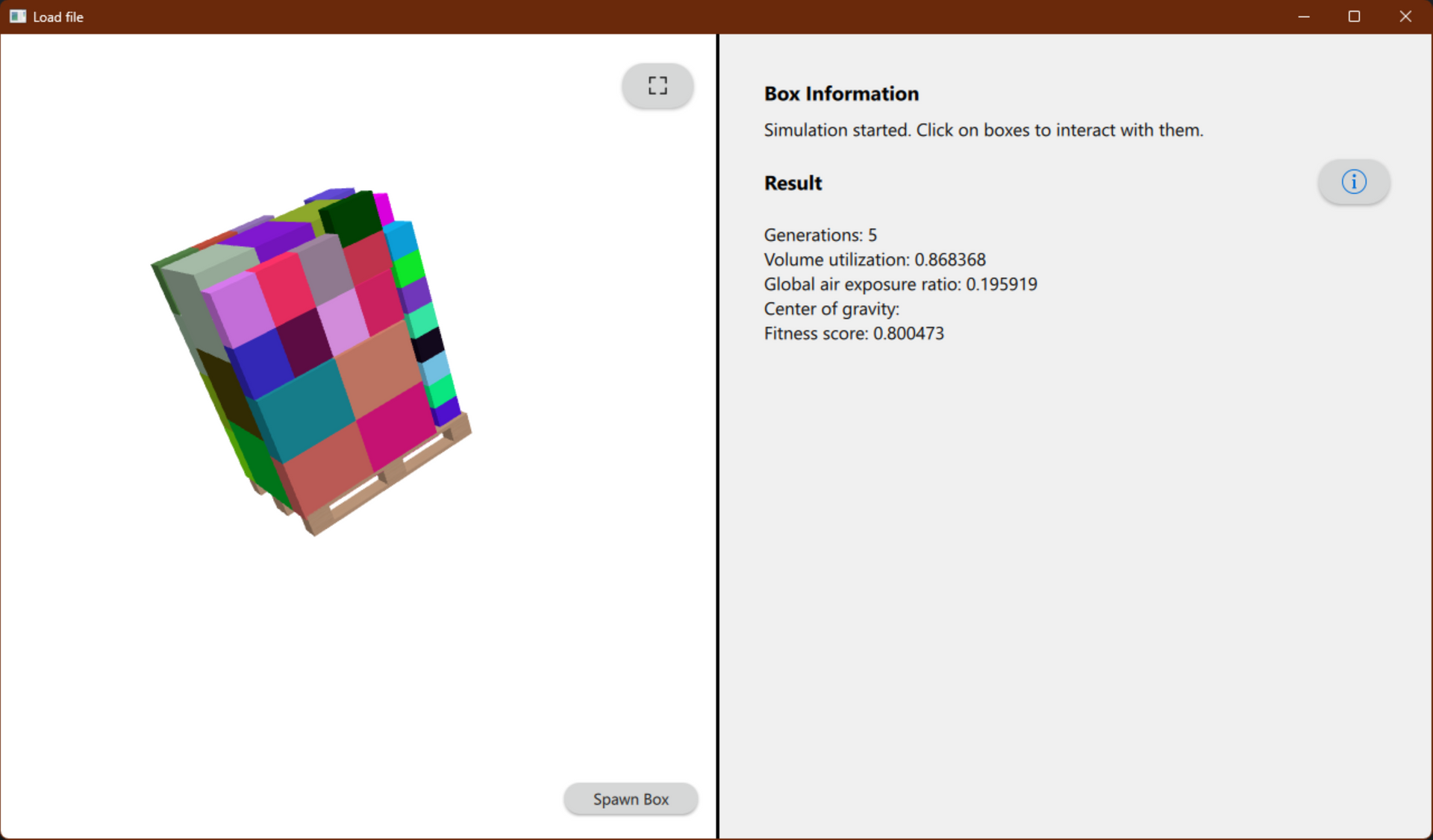

The algorithm operates on a server that interacts with the GUI. Users can control the number of optimization iterations through the interface. Though more iterations requires more computational time, they result in more efficiently packed pallets.

The GUI allows users to:

Choose from various standardized pallet types with different dimensions and weight limits

Upload and process product lists for server-side optimization

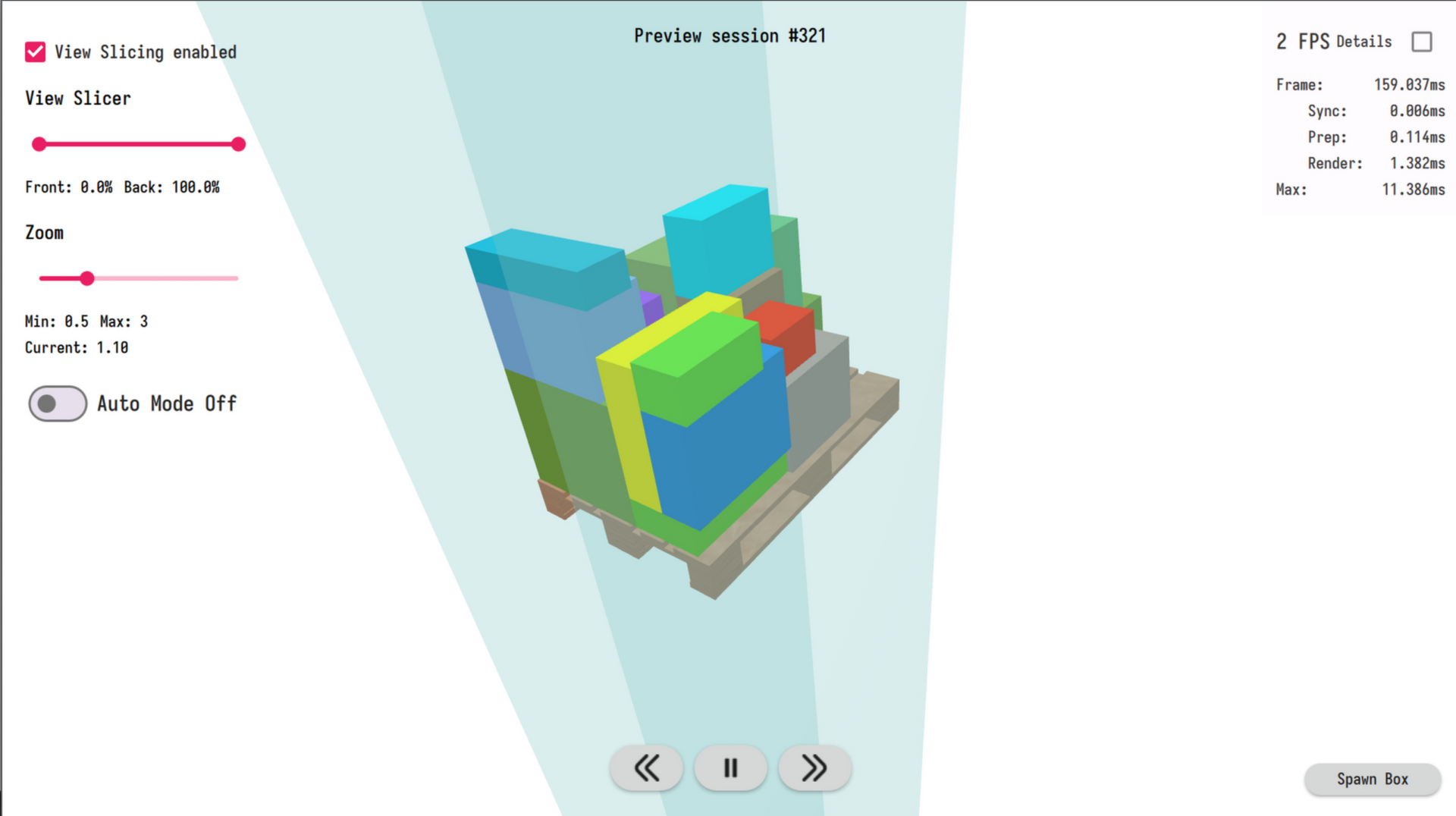

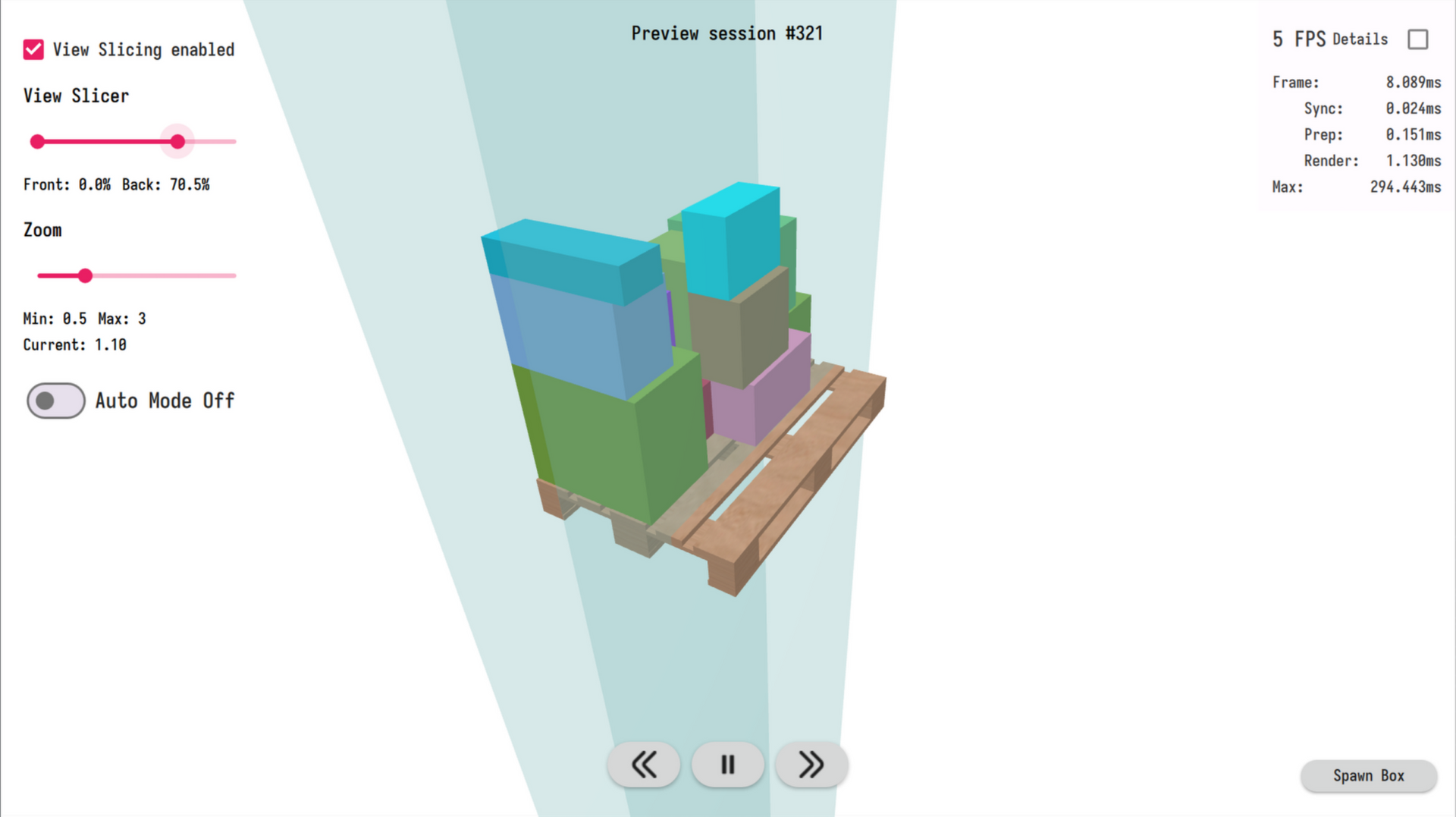

View box placement through an interactive 3D display with features like zooming, view slicing, and free navigation

This solution helps warehouse staff visualize the palletizing process before sending instructions to the ABB robot that performs the actual palletization.