Automated Warehouse Inventory Scheme

The project is developed in the context of the inventory checking in a factory warehouse. Normally, the inventories were shelved up in a numbered area with adhered barcodes/QR codes. In daily operation, the inventories would either be located or removed from the pallet racks to be dispatched or relocated. It must be guaranteed operators reach accurate stock every time. Hence, the project aims to implement an automated system to replace the current bulky indoor vehicles, while increasing the productivity of the workers, without human error factors. Besides, minimizing fatigue caused by the repetitive process to maintain a safe working environment would also be accounted for.

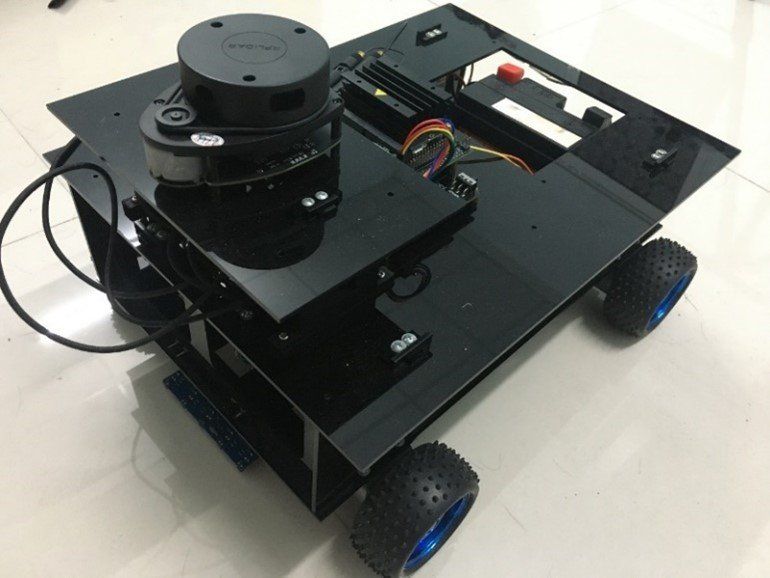

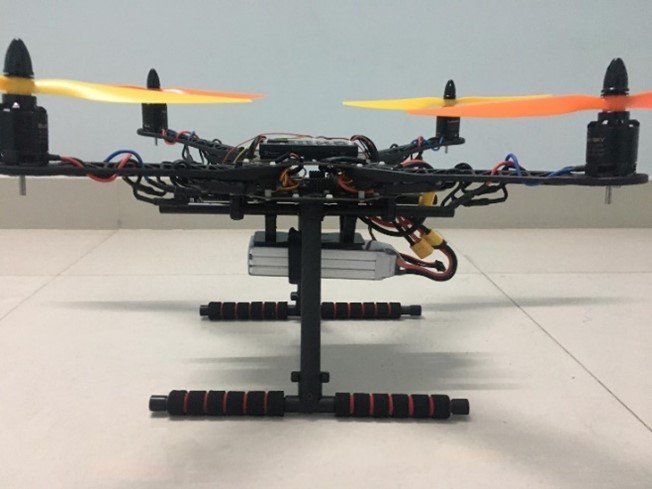

In the automated system, the Car and the Drone collaborate to perform the automated procedure. Due to the nature of a typical warehouse - highly stacked pallet racks, the Drone is required to be properly operated under certain requirements. Among them, the number of times the Drone fully completes its designated tasks would be assessed. Therefore, a solution to provide long-lasting power for the Drone and perform multiple inventories check before the Drone reaches its energy limitation should be considered. Based on the conducted research, the Car might function as a charger station for the Drone to charge itself every time it lands.

Website Demo

Test Run